In the mining industry, there is a continual quest for innovative and efficient technologies that can provide deeper insights into the composition and structure of geological materials. One such technology that has become a game-changer is Micro X-ray Fluorescence (microXRF, microEDXRF, µXRF, µEDXRF) Spectrometry. This state-of-the-art technology is revolutionizing mineral exploration, resource management, and quality control in mining.

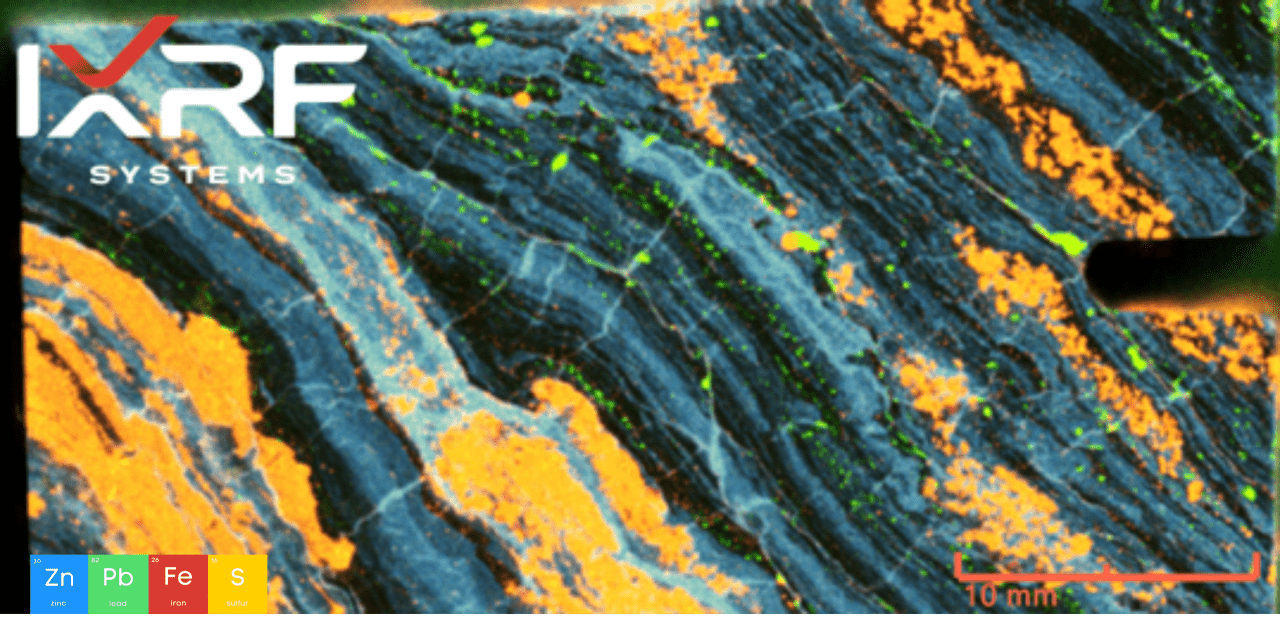

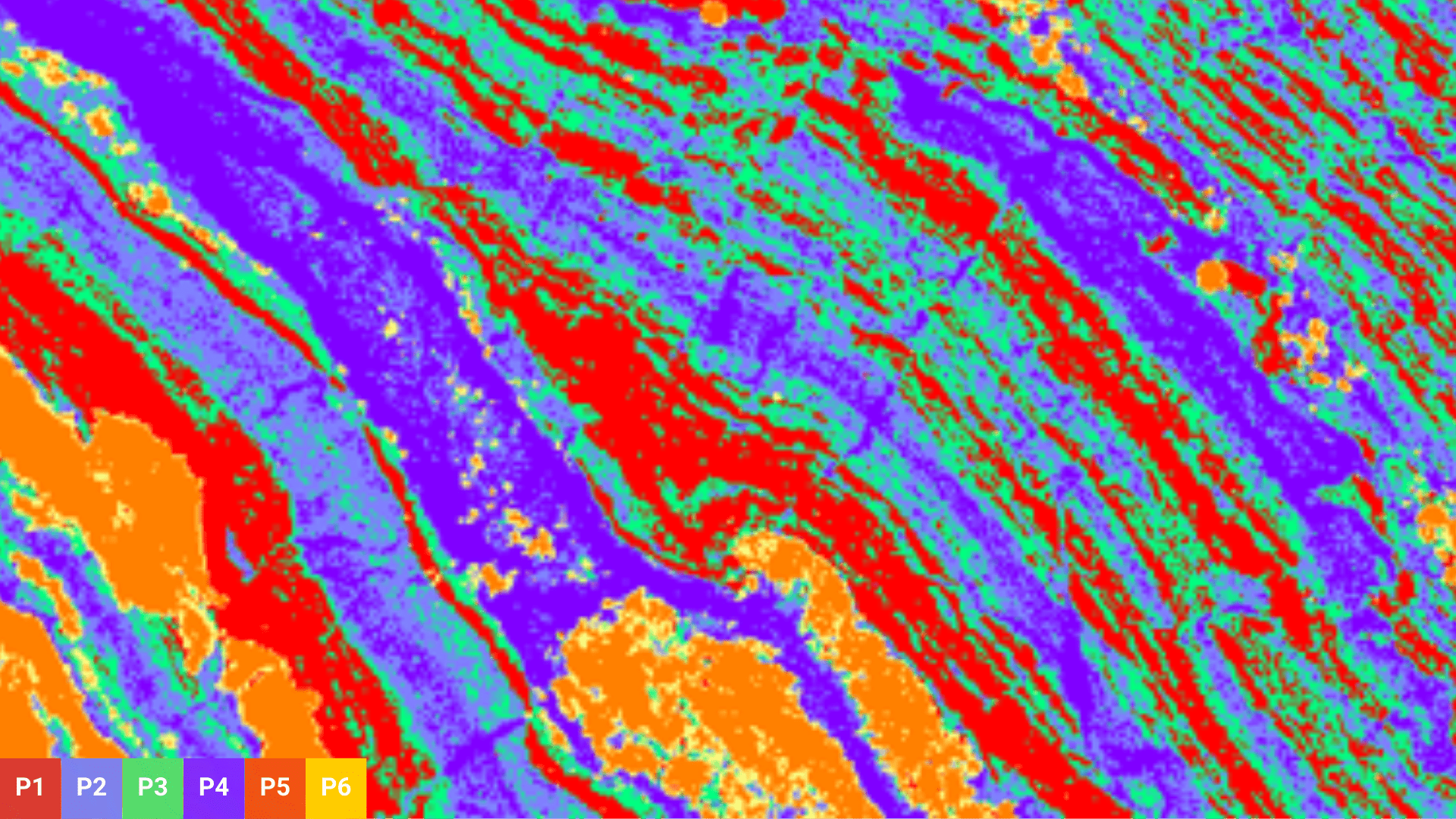

MicroXRF is an advanced method of X-ray fluorescence (XRF) spectroscopy, which allows for the analysis of geological specimens at a micro-scale level. This technique involves irradiating a specimen with a finely focused X-ray beam, causing the atoms within the sample to emit characteristic secondary (or fluorescent) X-rays. The resulting spectrum of these X-rays can be utilized to determine the sample’s elemental composition at the point of analysis. With sub-micron precision of the X/Y sample stage associated with MicroXRF instruments, exquisite elemental maps of thin section and core samples are obtained where each pixel, down to 5µm diameter, contains its own distinct elemental spectrum. This high resolution XRF mapping capability then allows further phase analysis, which is one of the most relevant mineralogy outcomes associated with MicroXRF.

Figure 1. A 2D microXRF elemental map of shale with laminated sphalerite.

One strength of MicroXRF lies in its non-destructive and non-invasive nature. This quality preserves the integrity of samples and allows for successive analyses without damaging or changing the specimen. MicroXRF offers real-time analysis and immediate results, which are vital for time-sensitive operations in the mining industry.

One of the key applications of MicroXRF in mining is mineral exploration. It offers improved geochemical analysis, enabling geologists to identify potential mineral deposits with greater accuracy. For instance, mineral alteration zones often surround ore bodies, and these zones contain particular elements that could signify the presence of valuable resources. By utilizing MicroXRF, explorers can identify these altered mineral phases and consequently enhance their predictive models for ore presence.

MicroXRF also plays a vital role in resource management, including ore grade control. This technology can rapidly and accurately determine the concentration of elements in the ore, including valuable elements (like gold, copper, or nickel) and potentially harmful elements (like arsenic, lead, or mercury). By leveraging this information, mining companies can efficiently plan extraction and processing operations while managing potential environmental risks.

Furthermore, MicroXRF assists in quality control by allowing continuous analysis of the mineral extraction process enabling mining companies to monitor and control the quality of their product. For instance, in the processing phase, MicroXRF can assess mineral separation, informing operators to make necessary adjustments which maintains product quality and minimizes waste.

Figure 2. A 2D microXRF phase map of shale with laminated sphalerite identifying six different phases using Principal Component Analysis (PCA).

Another key application of MicroXRF is in environmental monitoring within the mining industry. Mining activities can potentially release harmful substances into the environment. MicroXRF allows rapid on-site analysis of soil, water, and air samples for contamination, helping companies swiftly mitigate environmental impact.

Additionally, MicroXRF is instrumental in studying tailings (the waste material left after mineral extraction). Detailed analysis of tailings can reveal any residual minerals that may be valuable, offering the potential for further extraction. It also aids in understanding and managing the environmental implications of tailings, such as the potential leaching of harmful elements into groundwater.

Despite its numerous benefits, it’s important to acknowledge that MicroXRF has its limitations. It is most effective for the analysis of elements from sodium to uranium when they are present in high concentrations above 10 parts per million (ppm). Other techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) may be more appropriate for trace elements below 10 ppm.

Despite some limitations, the mining industry has significantly benefitted from the adoption of MicroXRF. Its non-destructive nature, real-time results, and high-resolution mapping capabilities provide unparalleled insights into geological materials, contributing to increased efficiency and profitability in the mining industry.

In conclusion, MicroXRF is paving the way for smarter, safer, and more sustainable mining practices. As this technology continues to evolve and improve, the benefits it offers will likely increase, further solidifying its role as a cornerstone in the mining industry.