Welcome to our in-depth FAQ blog series where we unpack complex scientific questions to provide our users with clear and straightforward answers from our very own expert and Director of Product Engagement, Ben Ruchte. Today, Ben will be diving deep into an often-asked question: “What advantages does high spatial resolution microXRF offer over conventional XRF systems (also known as ‘bulk XRF’)?”

Q1: Can you define high spatial resolution microXRF for us?

A1: High spatial resolution microXRF is a sophisticated method of X-ray fluorescence (XRF) that enables detailed material analysis at a microscopic scale. It essentially integrates the benefits of XRF, a renowned technique used for identifying the elemental composition of various materials, with the microscopic precision to examine small details, thus permitting highly localized, detailed analysis of elements.

Q2: How does microXRF differentiate from conventional XRF systems?

A2: Both microXRF and conventional XRF operate on the principle of applying X-ray energy to determine the elemental composition of a sample. However, the main point of differentiation lies in the spatial resolution. In microXRF systems, the X-ray beam is concentrated to a spot size as tiny as a few micrometers, enabling the analysis of intricate details that could potentially go unnoticed in conventional XRF systems where interrogation areas as large as several millimeters result in mixed elemental signal with no spatial detail.

Q3: Could you elaborate on why high spatial resolution enhances my analysis?

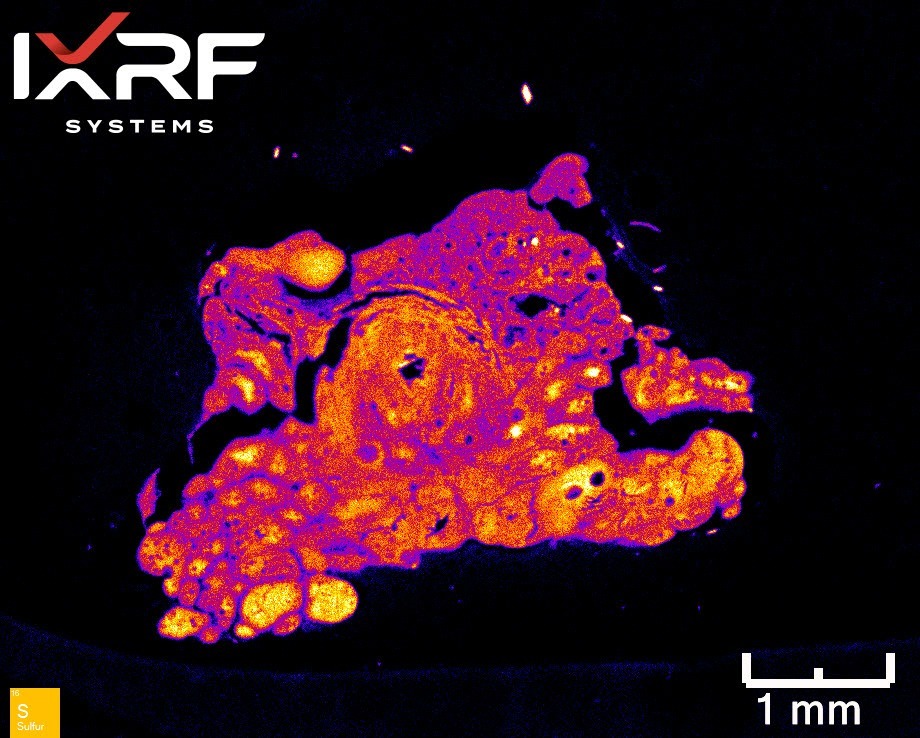

A3: Enhanced spatial resolution using microXRF offers the precise location of elements within your sample down to 5 micron spacing. This is particularly useful when you’re trying to pinpoint the exact location of an element, or when dealing with samples that exhibit high heterogeneity such as thin core sections for mining applications or printed circuit board interrogation of many disparate, small electronic features.

2D elemental map of a thin section of a human pancreas, collected at 5 micron spot size, displaying the distribution of Sulfur in Fire mode.

Q4: Are there specific applications where microXRF outperforms conventional XRF?

A4: Yes, indeed! MicroXRF truly excels in applications demanding high-resolution elemental mapping. These applications span a variety of scientific and engineering sectors including geological and environmental studies where understanding mineral composition is vital, forensics for detailed evidence analysis, art and cultural heritage preservation to study and maintain precious artifacts, electronics for quality control and failure analysis, and materials science where understanding the composition on a microscale can be pivotal.

Q5: How does the use of high spatial resolution microXRF affect the analysis duration?

A5: It’s worth noting that due to the smaller spot size, and the subsequent requirement to capture a larger number of data points (each pixel is a unique elemental spectrum containing both qualitative and quantitative information), the analysis duration can potentially be longer. However, the sheer level of detailed, spatial information that is returned can often justify this additional analysis time. Also, modern microXRF instruments, such as those developed here at IXRF Systems, incorporate cutting-edge technologies designed to optimize the speed of analysis.

Q6: Can microXRF systems handle large samples?

A6: Unlike some other microanalysis techniques, microXRF systems can accommodate and analyze large samples. This is an important advantage in fields like art conservation, where the sample could be a large painting or artifact. Additionally, samples can weigh in excess of 10kg when using our microXRF instruments from IXRF Systems.

Q7: What about sample preparation – does it require a specific method?

A7: Another significant benefit of microXRF over other techniques is that it requires minimal sample preparation, and, in many cases samples can be analyzed in their original, unmodified state. This is a substantial time-savings advantage and also reduces the risk of damaging delicate samples.

In conclusion, high spatial resolution microXRF has significantly advanced the field of materials analysis, providing an unprecedented level of detail, precision, and sensitivity. If you have more questions about our microXRF systems or any other products at IXRF Systems, don’t hesitate to reach out. We are dedicated to supporting you throughout your materials analysis journey.