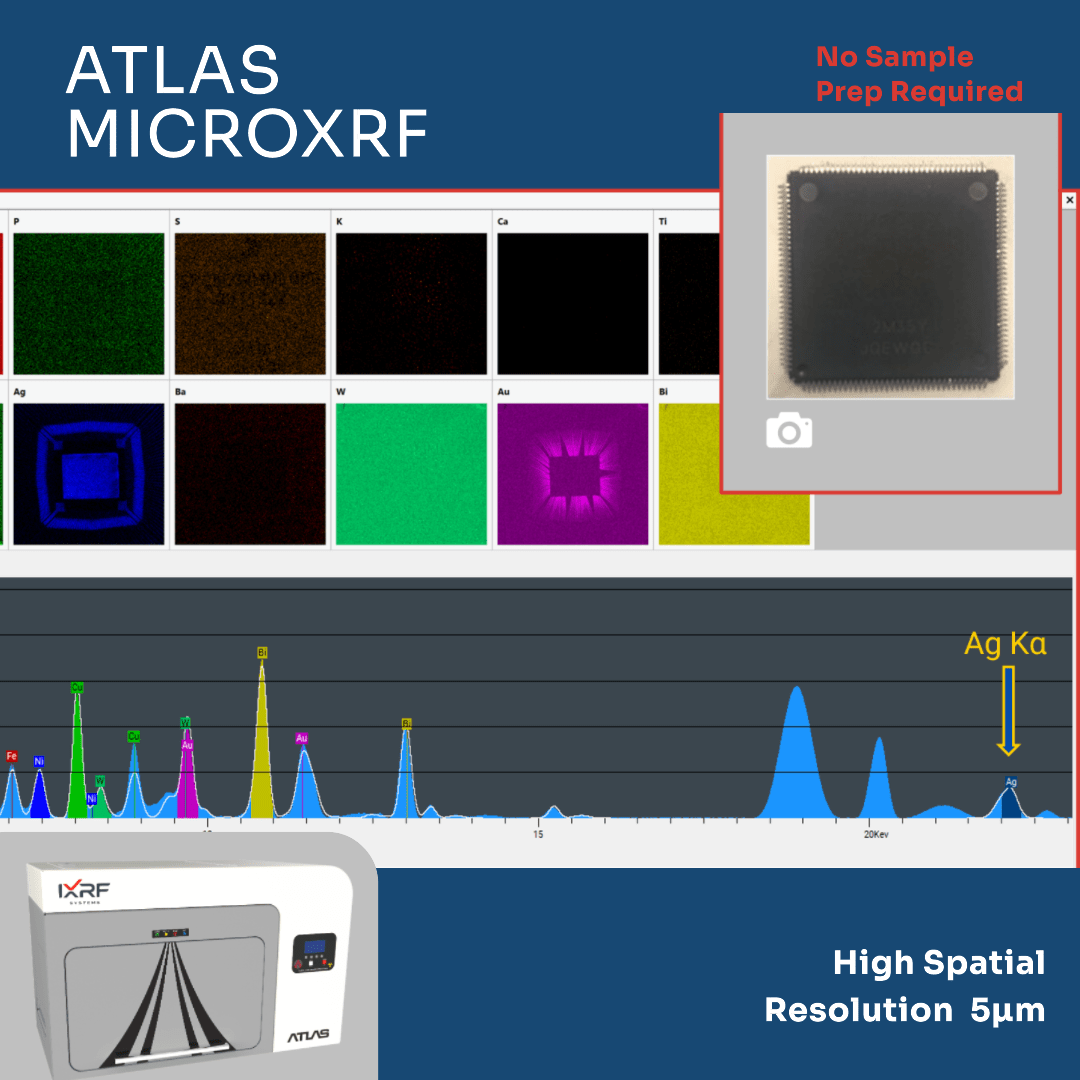

When incorporating IXRF System’s Atlas microXRF with its high spatial resolution and spot size as small as 5 microns, the advantages of using microXRF for quality control in Quad Flat Packages (QFPs) become even more apparent:

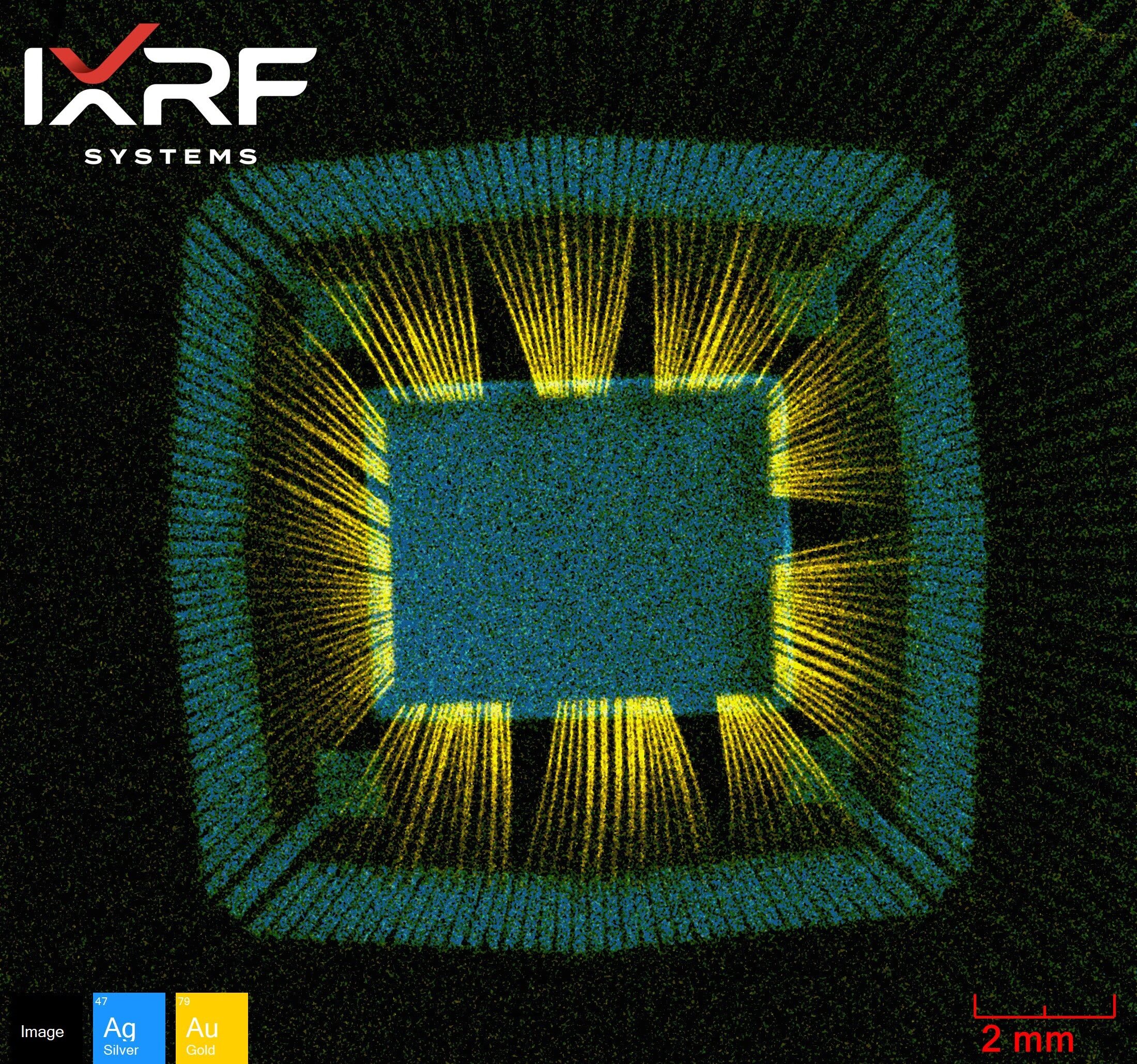

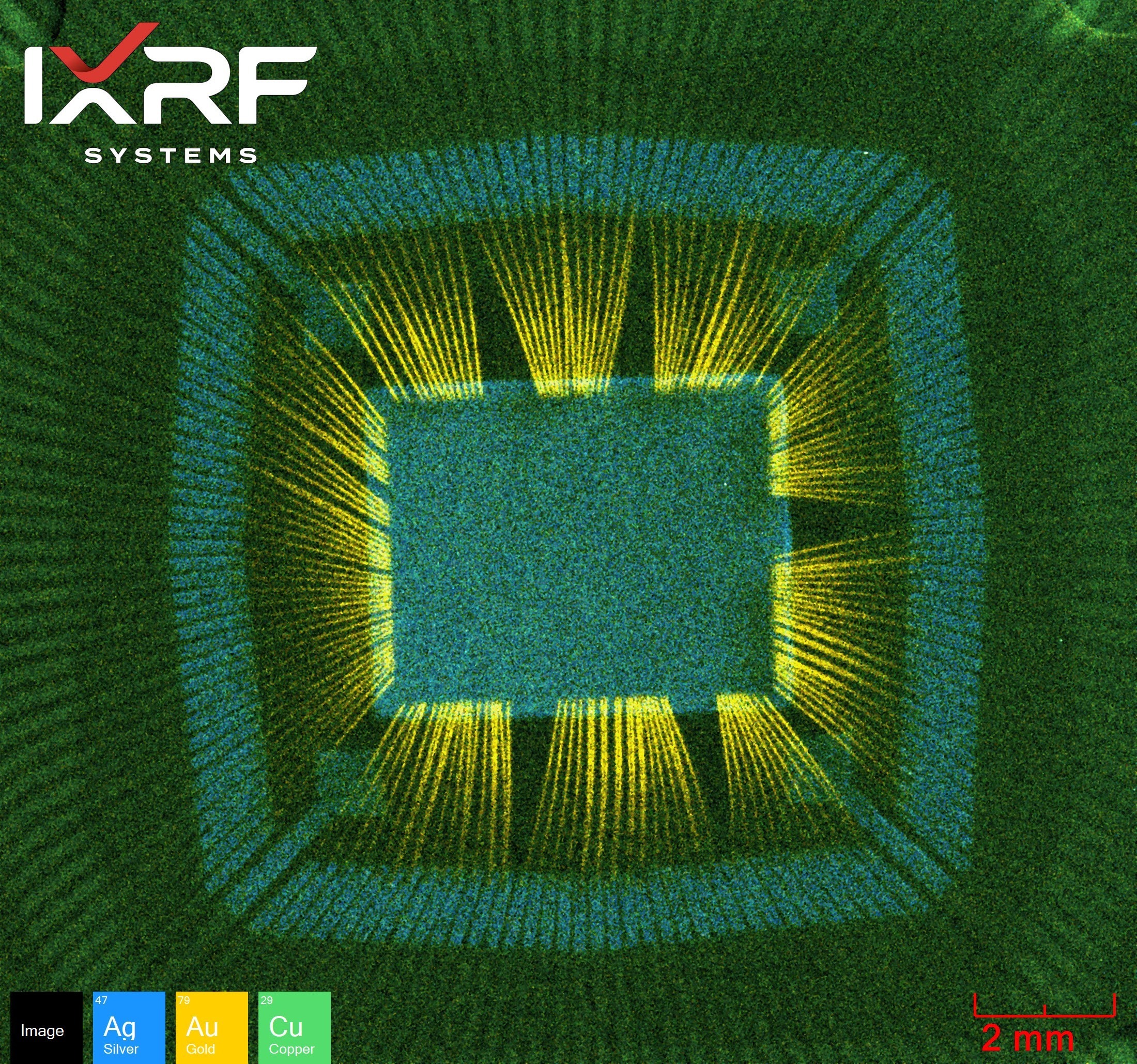

Enhanced Elemental Mapping with High Spatial Resolution

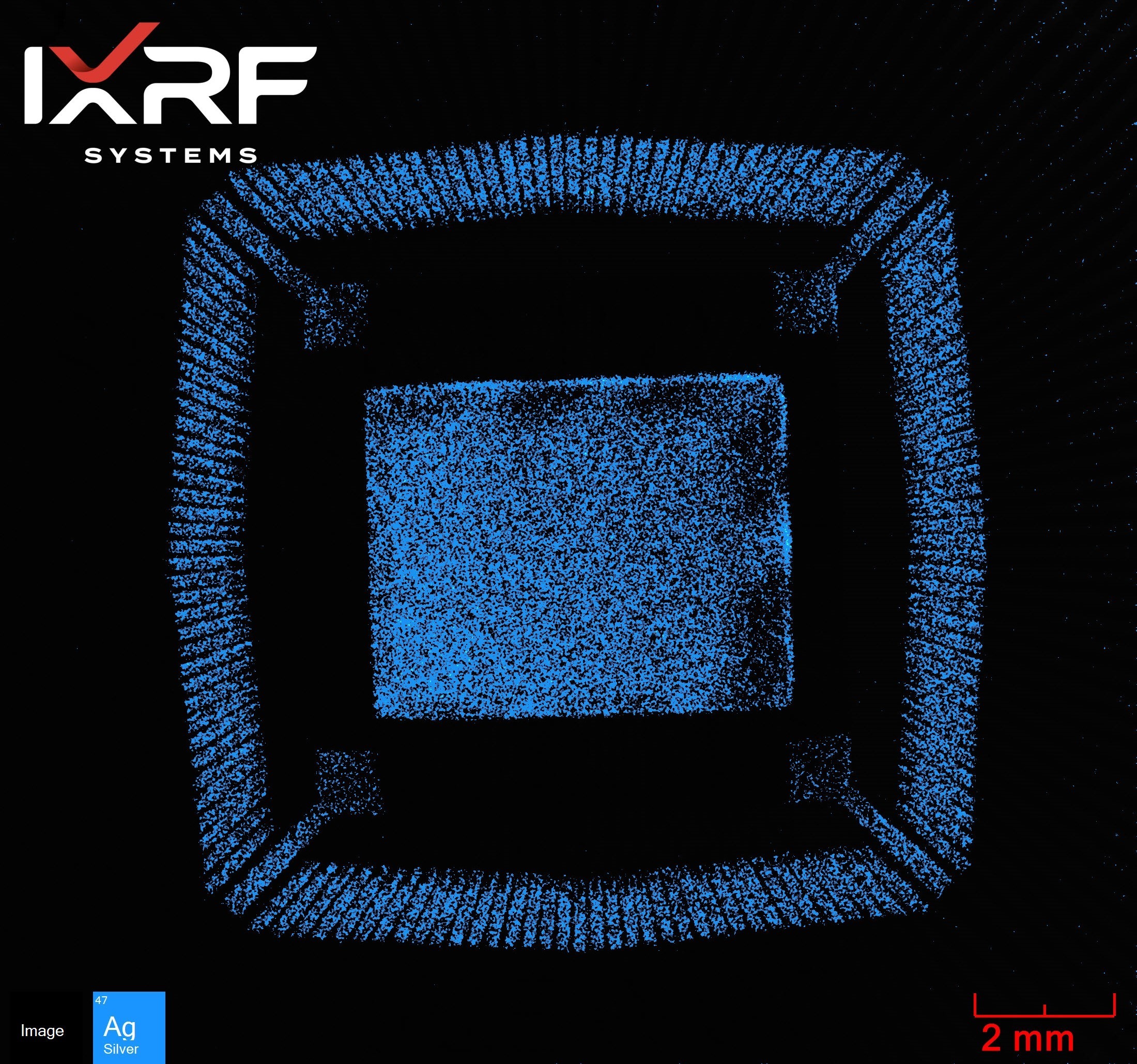

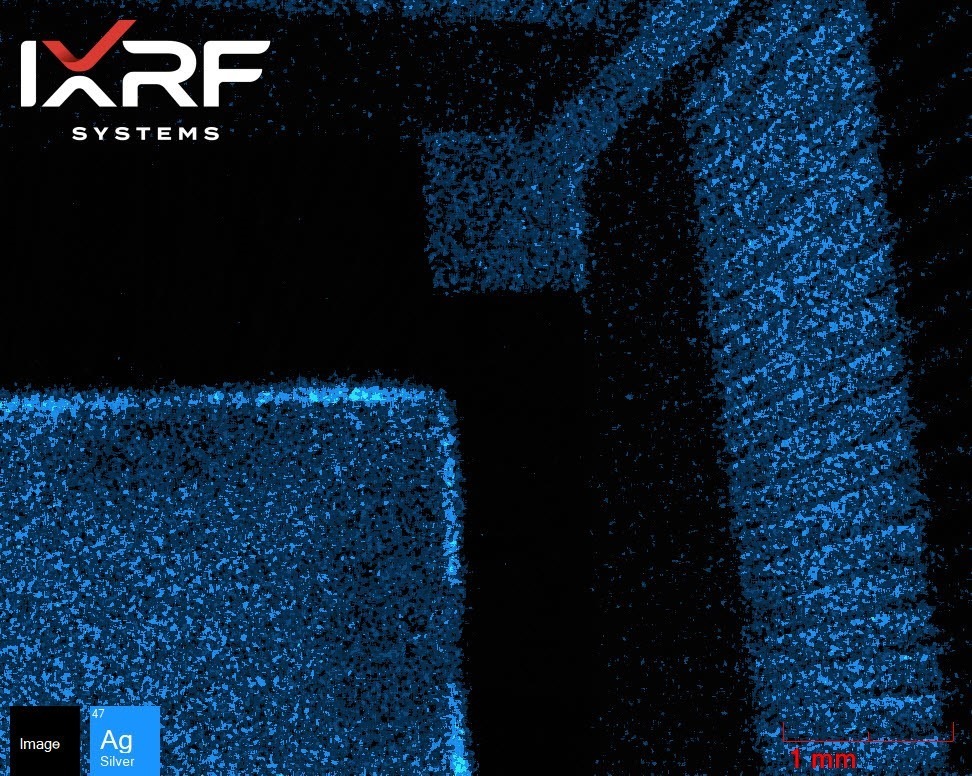

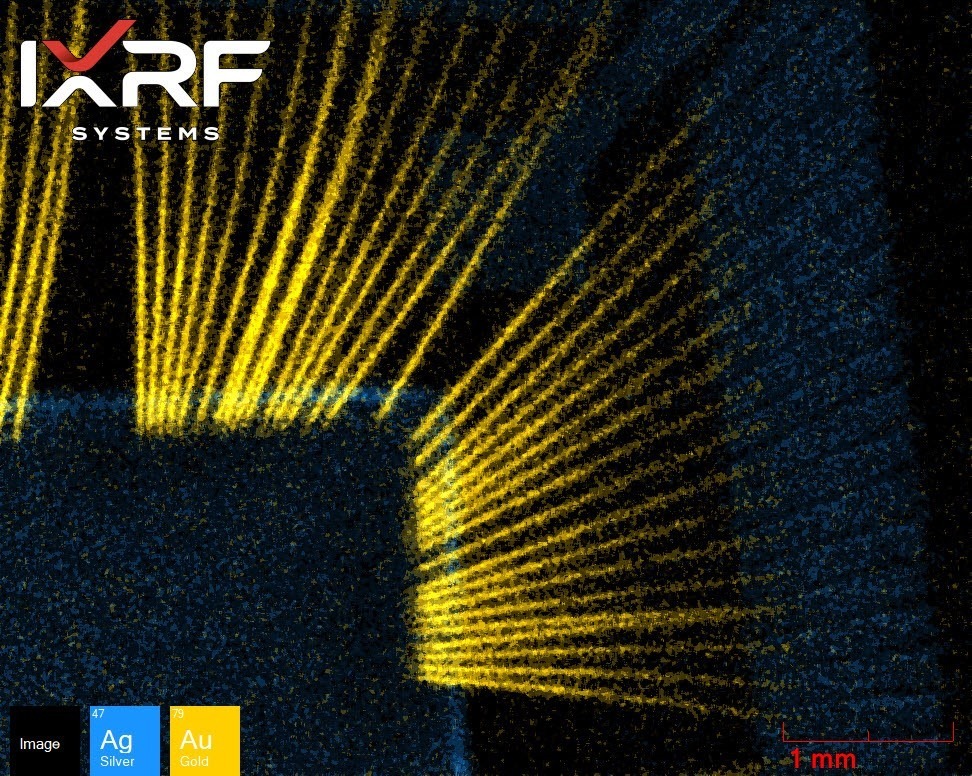

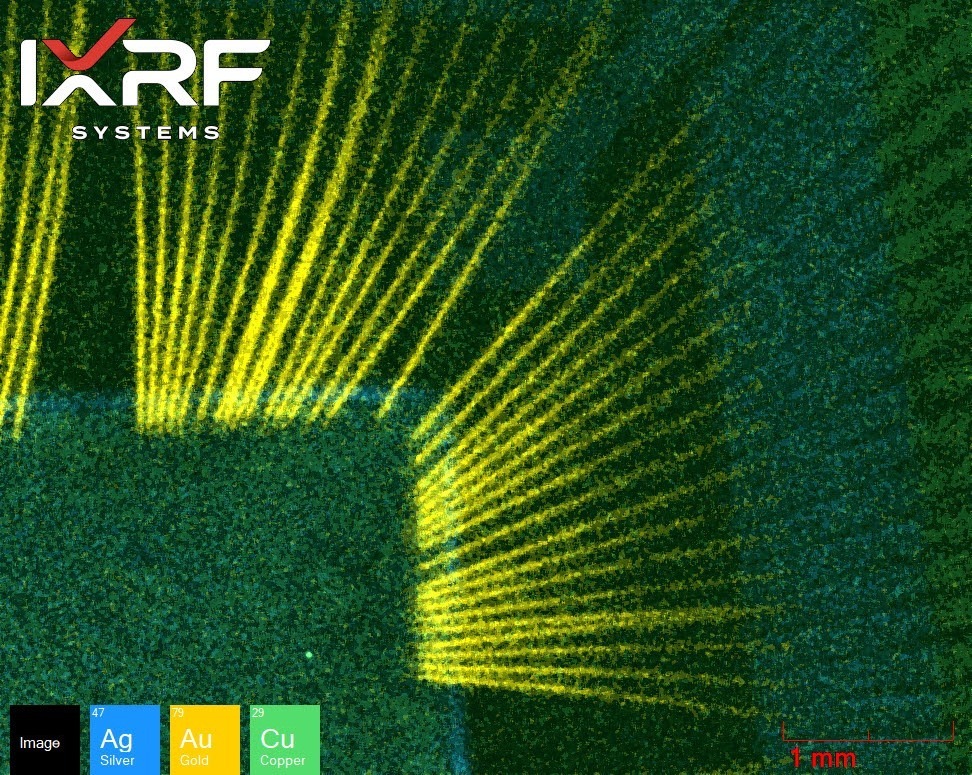

The Atlas microXRF‘s high spatial resolution allows for a detailed elemental map of the QFP structure. This level of detail is essential when analyzing components with intricate designs and multiple layers, ensuring each layer is of the expected composition. The 5-micron spot size allows for very targeted analysis, reducing the risk of cross-contamination between layers during the testing process.

Precise Trace Element Detection

The high spatial resolution of the Atlas microXRF allows for the detection of even trace amounts of elements or contaminants with greater precision. This is essential for ensuring that the materials used in QFPs are pure and free from any elements that could impair their function or long-term reliability.

Non-Destructive Analysis of Fine Features

Traditional microXRF systems might require a larger area for reliable analysis, limiting their utility for small or delicate features within the QFP. With a spot size as small as 5 microns, the Atlas microXRF can analyze extremely fine features non-destructively, providing comprehensive quality control without impairing the integrity of the component.

Figure 1: Elemental maps of QFP Logic Chip collected on the Atlas M microXRF. The component was analyzed as is, with the top surface plastic mold compound intact, revealing intricate interworkings of the chip, including the Ag frame, the Au wires, and the Cu leads.

Accurate Layer Thickness Measurement

The high spatial resolution and small spot size enable the Atlas microXRF to measure layer thickness accurately. This is particularly vital for QFPs where the thickness of various layers, such as solder masks or die attach materials, must meet stringent specifications for the component to function properly.

Automated, High-Throughput Analysis

While most microXRF systems offer the advantage of automation for high-throughput analysis, the added precision of the Atlas system ensures that even in a high-speed, automated environment, no detail is too small to escape notice. This level of automation, combined with the system’s high accuracy, makes it an ideal choice for quality control in large-scale QFP manufacturing.

Incorporating IXRF System’s Atlas microXRF into the quality control process for QFPs ensures exceptionally high levels of accuracy and detail, making it an invaluable tool for ensuring component reliability and performance.

Discover how the Atlas microXRF from IXRF Systems enhances quality control in QFP manufacturing. Explore its benefits and understand its impact on component reliability.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries.