At IXRF Systems, we are proud to contribute to cutting-edge research that supports sustainable energy and industrial innovation. Recently, our Atlas Micro-XRF spectrometer played a role in a preliminary study investigating the performance of Mn-doped cobalt-titania (Co/TiO2) catalysts for Fischer-Tropsch (FT) synthesis. While still under review and not yet peer-reviewed, this research is significant for its potential to enhance the production of clean synthetic fuels and valuable chemical products, paving the way for a more sustainable future. However, it is important to note that these findings should be considered preliminary and only conclusive after peer review.

Importance of the Research

Transitioning to renewable energy sources is one of the most urgent global challenges. Fischer-Tropsch synthesis, a well-established industrial process, offers a pathway to convert alternative carbon sources such as biomass, industrial waste, and captured CO2 into synthetic fuels and chemicals. These processes can provide carbon-neutral alternatives to traditional fossil fuels, helping to mitigate climate change.

One of the key challenges in Fischer-Tropsch synthesis is catalyst optimization. Catalysts based on cobalt (Co) are widely used due to their high selectivity for long-chain hydrocarbons and ability to operate efficiently with low CO2 emissions. However, tuning the catalyst’s composition to maximize the production of high-value products—like alcohols and olefins—can significantly improve the efficiency and economic viability of the process.

In this context, the role of manganese (Mn) as a promoter for cobalt-based catalysts has drawn significant attention. Mn has been shown to influence the formation of cobalt carbide (Co2C), a phase that enhances the selectivity toward alcohols and olefins. The research explores how varying Mn content in Co/TiO2 catalysts impacts the formation of cobalt carbide and the spatial distribution of active catalyst phases within the material. Understanding these factors is crucial for optimizing catalyst performance and achieving better product yields.

Practical Applications of the Research

Although preliminary, this research’s results directly apply beyond the academic sphere. Industries involved in synthetic fuel production, chemical manufacturing, and the energy sector stand to benefit from improved catalysts that are more selective, efficient, and stable over longer reaction periods.

- Synthetic fuel production: Industries using Fischer-Tropsch technology can apply these preliminary findings to fine-tune their processes for cleaner, carbon-neutral fuels, reducing reliance on fossil fuels.

- Chemical and petrochemical industries: The ability to selectively produce olefins and alcohols from syngas enhances the production of essential feedstocks for various chemicals and materials, including plastics, solvents, and polymers.

- Environmental impact: This research supports circular economy initiatives by converting waste products into valuable fuels and chemicals, helping meet global net-zero carbon goals.

The Role of Micro-XRF in Catalyst Research

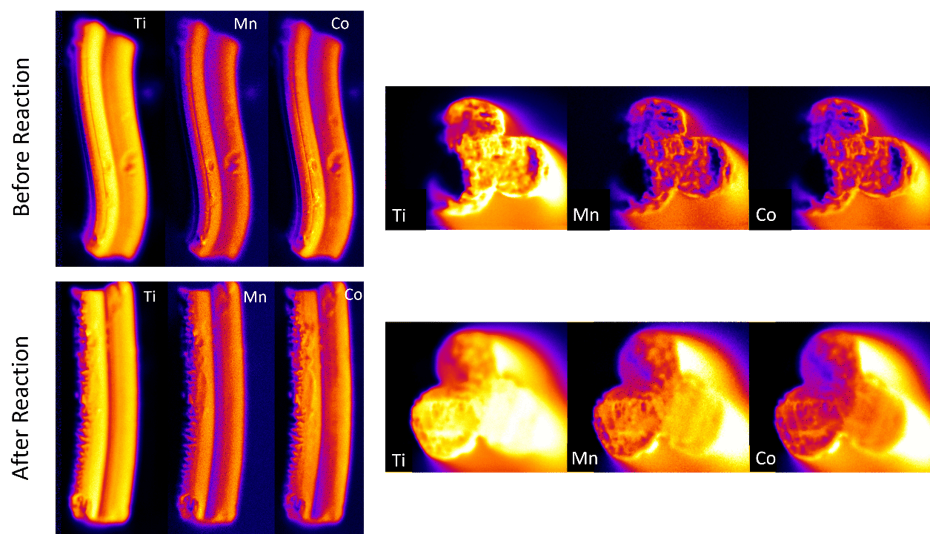

Our Atlas Micro-XRF spectrometer was integral to this research by providing high-resolution elemental mapping of the Mn-doped cobalt-titania catalyst samples. Micro-XRF was used to analyze the distribution of manganese (Mn) and cobalt (Co) within the catalyst before and after a 300-hour reaction under industrial Fischer-Tropsch conditions.

The 5-micron spot size capability of the Atlas Micro-XRF system enabled the researchers to gain detailed insights into how the elements were distributed across the catalyst pellets. This high spatial resolution was critical in visualizing the egg-shell distribution of cobalt carbide (Co2C), which forms on the periphery of the catalyst extrudates. The study revealed no significant Mn or Co distribution changes by comparing the elemental maps before and after the reaction, suggesting that the catalyst was stable under reaction conditions.

Figure 1: MicroXRF images of the lateral faces (left) and cross-sections (right) of the 3 wt. % Mn samples extracted before and after reaction for 300 h. The Mn and Co are found to be co-located, and no significant changes were found before or after the reaction.

Why Micro-XRF?

- Non-destructive analysis: Micro-XRF allows for detailed elemental mapping without damaging the sample, preserving it for further analysis.

- High spatial resolution: Achieving a 5-µm spot size enables precise mapping of complex catalyst structures.

- Comprehensive element detection: The system can detect various elements, from light to heavy metals, making it ideal for heterogeneous catalyst analysis.

For this research, the combination of micro-XRF with other advanced techniques, such as X-ray diffraction computed tomography (XRD-CT) and pair distribution function computed tomography (PDF-CT), provided a holistic understanding of how the distribution and phases of cobalt and manganese affect catalytic performance.

Acknowledgments

We sincerely thank Andrew Beale and Danial Farooq from University College London and his team for leading this vital research. We would also like to thank Ben Ruchte from IXRF Systems for his valuable contributions in generating the micro-XRF data crucial to this study. Their collaboration has been essential in advancing our understanding of catalyst performance under industrially relevant conditions.

Future Outlook

As industries increasingly seek sustainable solutions, the importance of optimizing catalyst performance cannot be overstated. The findings from this preliminary research will guide the development of more efficient and selective catalysts, enhancing the production of synthetic fuels and chemicals from renewable and waste materials.

IXRF Systems supports groundbreaking research by providing state-of-the-art analytical tools like the Atlas Micro-XRF. Whether in academic research or industrial applications, micro-XRF is a powerful technique that helps scientists understand material composition at a granular level, driving innovations that can reshape our energy landscape and create a more sustainable future.

For more information on how the Atlas Micro-XRF can support your research or industrial applications, visit www.ixrfsystems.com or contact us at info@ixrfsystems.com.

Note: This report is preliminary and has yet to undergo peer review. As such, it should not be considered conclusive, and further validation through the peer-review process is necessary.

Article Reference: Chemical Imaging of Carbide Formation and Its Effect on Alcohol Selectivity in Fischer Tropsch Synthesis on Mn-Doped Co/TiO2 Pellets