Accurate characterization of multi-layer thin films is a critical aspect of materials science and engineering. IXRF Systems’ ATLAS micro-scale X-ray Fluorescence (microXRF) spectrometer provides a practical tool for analyzing film composition and structure. This article outlines the system’s capabilities, calibration practices, key applications, and practical guidelines for effective analysis.

How MicroXRF Works

MicroXRF is a non-destructive technique that uses X-ray fluorescence to determine the elemental composition of materials. The ATLAS microXRF system directs a focused X-ray beam onto the sample surface, causing the emission of secondary X-rays specific to each element. These signals are detected and analyzed to provide both qualitative and quantitative results, including the detection of contaminants at parts per million (ppm) levels.

Due to its spatial resolution and sensitivity, the system is well-suited for evaluating multi-layer thin films. It can characterize each layer’s elemental composition, assess composition gradients, determine layer thicknesses, and map uniformity and potential defects.

Calibration Best Practices

Effective calibration ensures reliable and reproducible results. Consider the following guidelines:

- Use Standard Reference Materials (SRMs):

- Select SRMs that align closely with the sample’s composition and thickness to ensure calibration accuracy.

- Regular Calibration Checks:

- Periodically test known standards to verify system accuracy, especially when working with varied sample types.

- Optimize System Parameters:

- Adjust settings such as tube voltage, current, and detector configuration to improve signal quality, particularly when analyzing trace elements or fine layer structures.

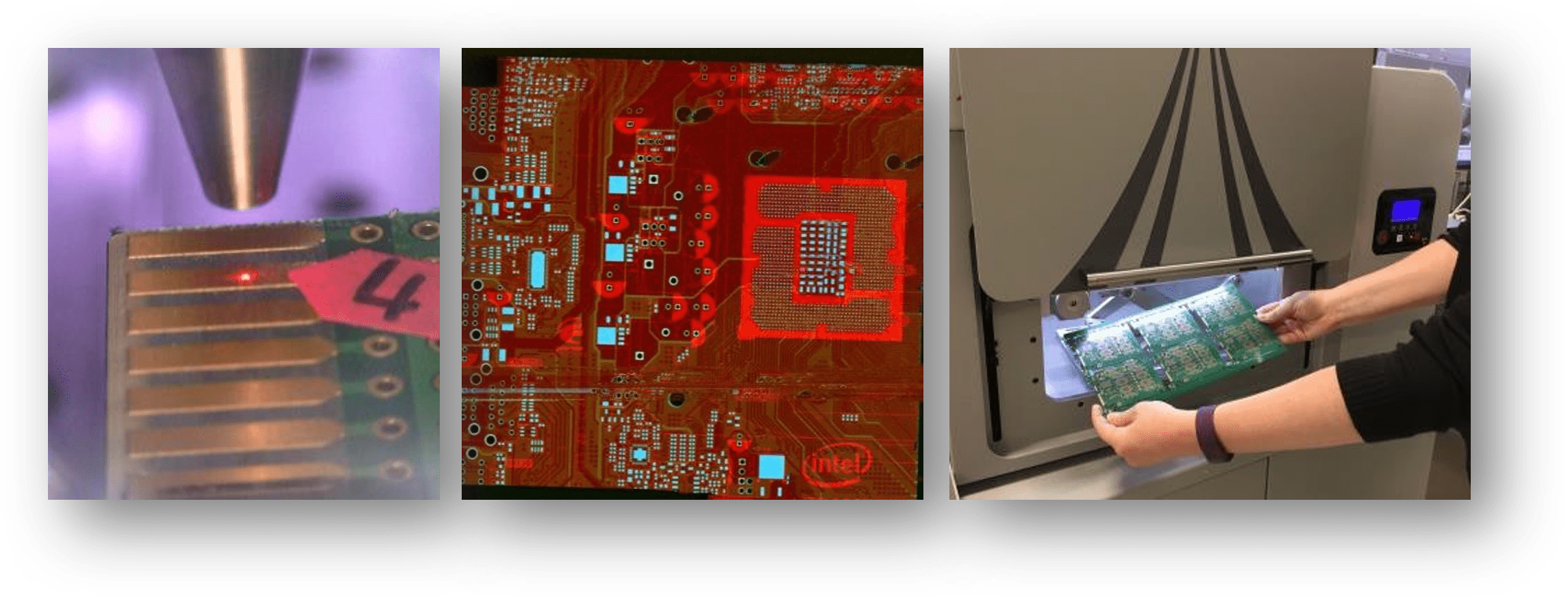

Figure 1. Left: Close-up view of a circuit board contact point undergoing microXRF analysis to measure thin film composition and structure. Middle: High-resolution 2D elemental intensity map of a printed circuit board (PCB), revealing spatial distribution of key elements across the surface. Right: Set up the ATLAS M microXRF system to analyze a large-format PCB, supporting comprehensive multi-layer thin film characterization.

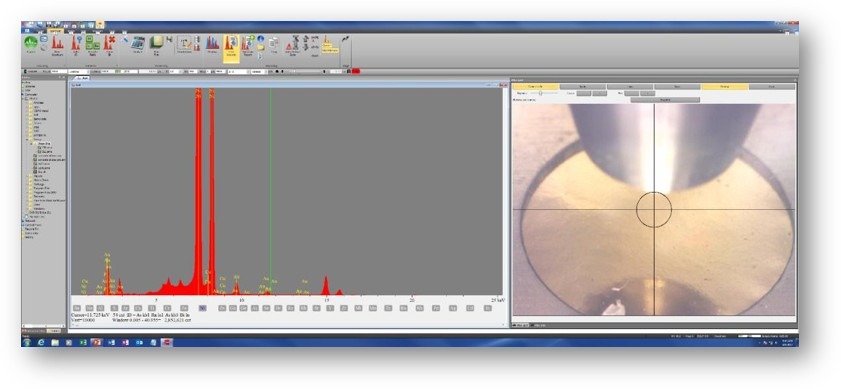

Figure 2. Screen capture of the Iridium Ultra Multi-Layer Thin Film Analysis software interface during a scan of certified thin film standards. The image illustrates layer-specific spectral data and real-time quantitative results used for calibrating and evaluating multi-layer film composition and thickness.

Key Applications of Multi-Layer Thin Film Analysis

The ATLAS microXRF system is applicable in a broad range of research and industrial settings:

- Semiconductor Manufacturing:

- Supports quality control and process monitoring by providing measurements of thin film thickness and elemental composition in integrated circuits.

- Aerospace and Automotive Coatings:

- Assists in characterizing protective and functional coatings to verify composition and thickness for performance and compliance.

- Photovoltaics and Renewable Energy:

- Analyzes thin film materials in solar cells to help optimize efficiency and durability.

- Optical Coatings:

- Used to evaluate AR and HR coatings, bandpass and dichroic filters, and laser optics across applications including telecommunications, fluorescence microscopy, lighting, cameras, and sensors.

- Waveguides and Integrated Photonics:

- Enables detailed characterization of photonic integrated circuits, such as modulators and multiplexers, supporting development in telecommunications and data transmission.

- Display Technology:

- Provides thin film analysis for LCDs, OLEDs, and AR devices, contributing to performance assessment and consistency.

- Cultural Heritage and Art Conservation:

- Offers a non-invasive method for examining historical artifacts and artworks, aiding in preservation strategies and material identification.

Essential Guidelines: Do’s and Don’ts

Do:

- Use Matched Standards: Choose standards that closely reflect your sample’s material properties.

- Check Calibration Routinely: Perform regular verification with standards to ensure ongoing accuracy.

- Adjust Settings for Specific Needs: Tune instrument settings based on the sample and analytical objectives.

Don’t:

- Skip Calibration: Omitting this step can compromise result accuracy.

- Disregard Layer Interactions: Consider how adjacent layers may influence results.

- Ignore Routine Maintenance: System upkeep is essential for maintaining measurement integrity.

Conclusion

IXRF Systems’ ATLAS microXRF provides a practical, non-destructive method for multi-layer thin film analysis. It facilitates the characterization of layer composition, thickness, and uniformity, as well as the detection of contaminants and defects. With proper calibration and usage, the system accommodates a wide array of applications, ranging from advanced manufacturing to conservation science, delivering meaningful data to inform research and development.