Electronic components are everywhere in our modern world. It is imperative that these components are reliable, as they control extremely important systems from every day items, to electronically controlled military equipment as well as a variety of aerospace equipment. To assure this reliability components must go through a battery of tests. XRF analysis is an irreplaceable tool for the semiconductor industry to not only guarantee but to also certify their products. Electrical or photonic circuits are one of these components that are the foundation for so many other products. These circuits begin their lives on silicon wafers. As the wafers and associated circuits and boards become more specialized they require different types of testing.

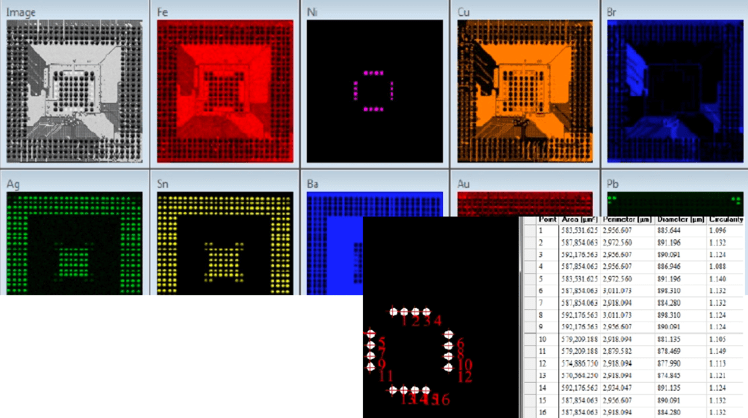

IXRF Systems’ ATLAS SEMI can analyze for:

- bump inspection

- CMOS image sensors (CIS)

- corrosion resistance coating

- Cu CMP control at BEOL

- film stack

- light elements

- metal film stack composition such as CIGS

- multi-stack structures

- Pb measurement for Whiskers

- redistribution layer (RDL)

- Sn/Ag Bump/Pillar measurements

- sputtering targets

- thermal barrier coating

- thick mono-layers

- thickness and composition control

- thin Film/Coating thickness measurements

- ultra thin films

- under bump metallization (UBM)

- wafer-level packaging (WLP)