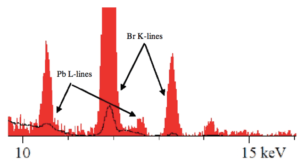

The Restriction of Hazardous Substances (RoHS) is a compliance directive that holds companies directly responsible for ensuring their electrical and electronic equipment (EEE) conform to strict standards. This directive requires that products cannot contain lead, cadmium, mercury, hexavalent chromium, polybrominated biphenyls (PBBs), polybrominated diphenyl ethers (PBDEs), and four different phthalates above specifically set amounts. These restricted materials are hazardous to the environment and pollute landfills, and are dangerous in terms of occupational exposure during manufacturing and recycling.

The European Union was the first to adopt such directives, but since its inception, California, China, Korea, Turkey, Taiwan and India, have joined the push for compliance and responsibility by creating similar requirements. RoHS has quickly become an imperative for companies wanting to participate in the global market.

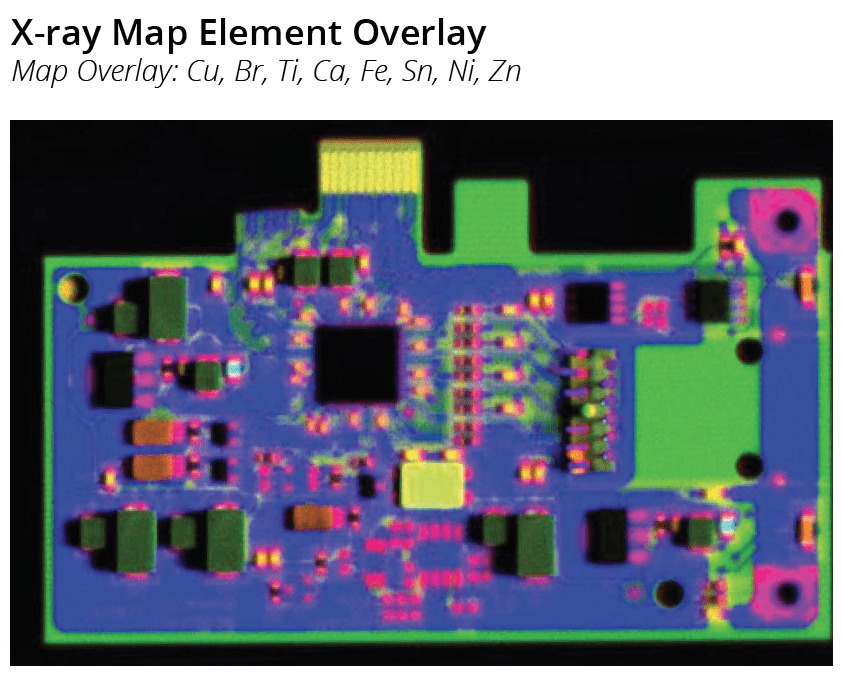

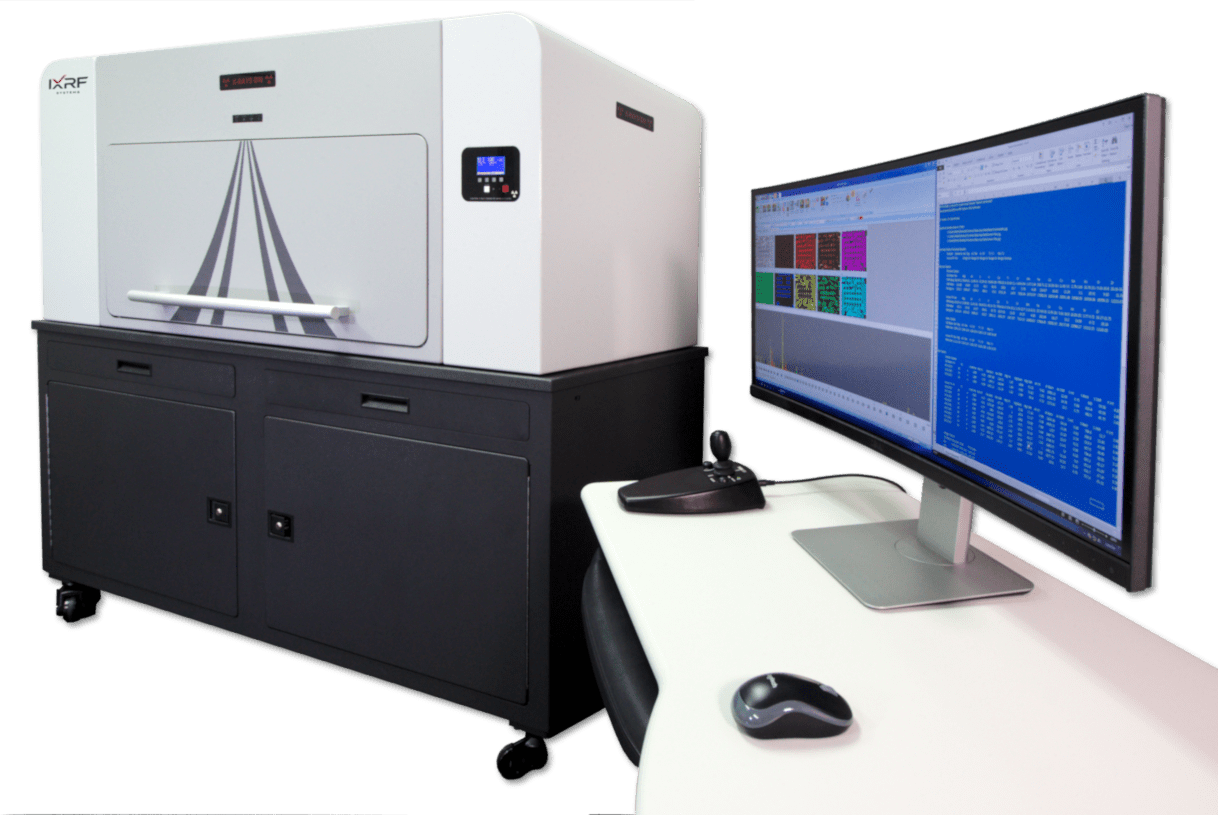

X-ray Fluorescence is the preferred method for nondestructively testing materials for RoHS compliance. Micro X-ray Fluorescence (μ-XRF) analysis is an accurate, rapid, test method for elemental analysis. The IXRF Systems ATLAS μ-XRF unit is equipped with micron-level spatial resolution capability for spot analysis as well as elemental mapping.

RoHS specifies maximum levels for the following six restricted materials:

- Lead (Pb): <1000 ppm

- Mercury (Hg): <100 ppm

- Cadmium (Cd): <100 ppm

- Hexavalent Chromium (Cr VI): <1000 ppm

- Polybrominated Biphenyls (PBB): <1000 ppm

- Polybrominated Diphenyl Ethers (PBDE): <1000ppm