Staying ahead of industry challenges requires innovative solutions in the dynamic world of steel manufacturing. Enter Veritas, IXRF Systems’ groundbreaking advancement in MacroXRF technology. Designed to lead the field of elemental analysis, Veritas is revolutionizing how Advanced High-Strength Steel (AHSS) and Ultra-High-Strength Steel (UHSS) slabs are analyzed. This article explores the remarkable capabilities of Veritas MacroXRF, drawing on recent research insights, and illuminates how it’s reshaping the landscape for steel manufacturers, metallurgists, and industrial engineers.

Why Choose Veritas MacroXRF?

Comprehensive Elemental Analysis Redefined

Veritas MacroXRF is not your average instrument; it’s a comprehensive solution engineered for superior performance in elemental analysis. Its capabilities extend far beyond traditional methods, offering an all-encompassing approach that keeps pace with the rigorous demands of modern industry.

Unmatched 2D Mapping Capabilities

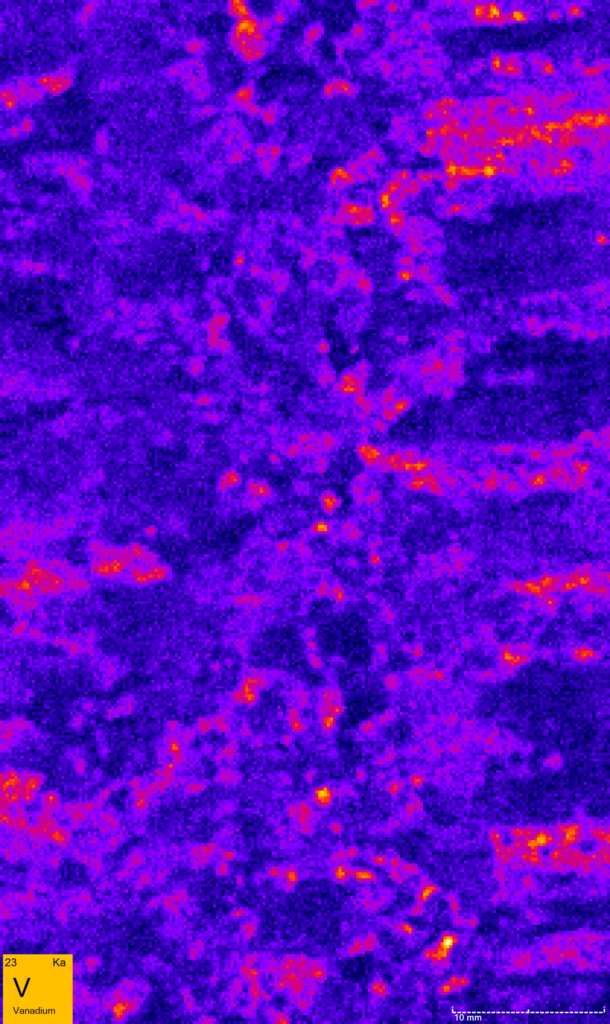

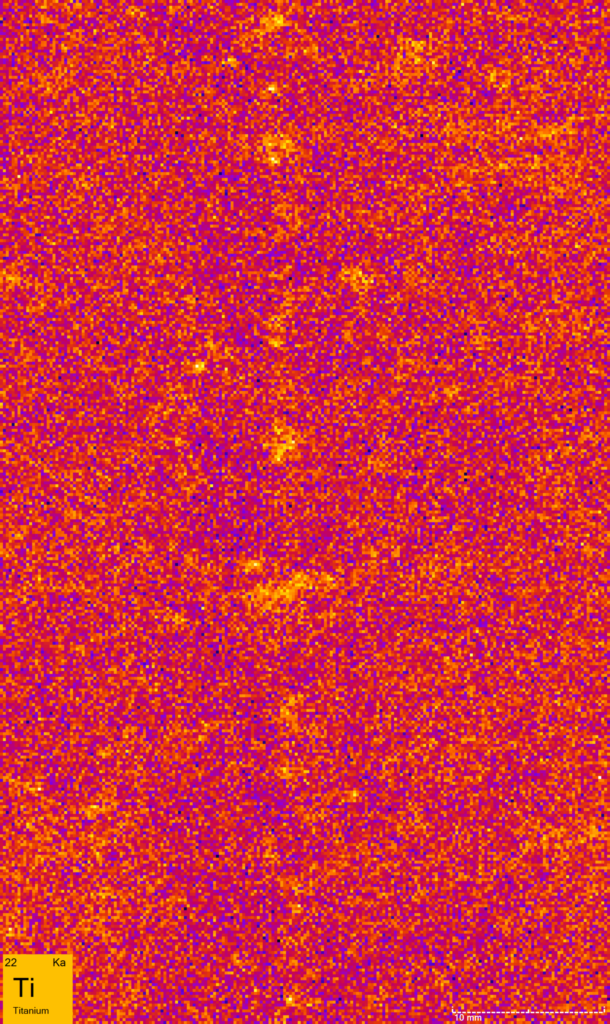

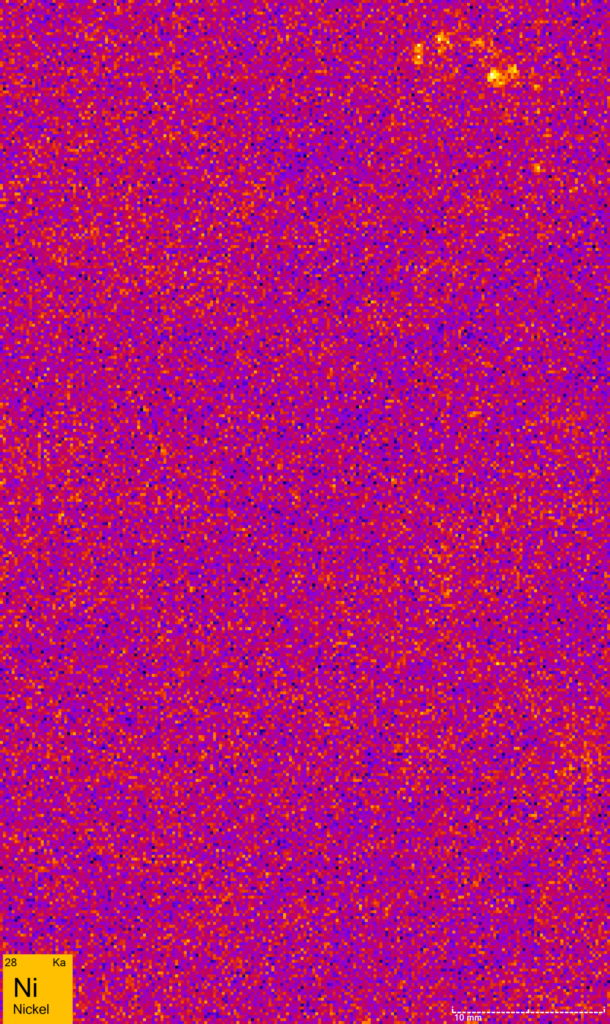

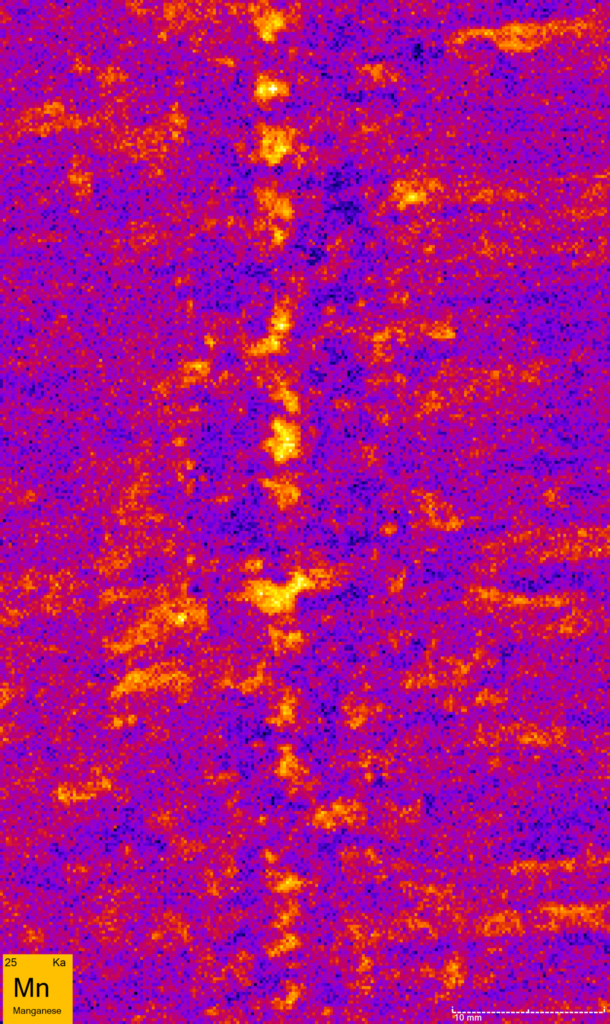

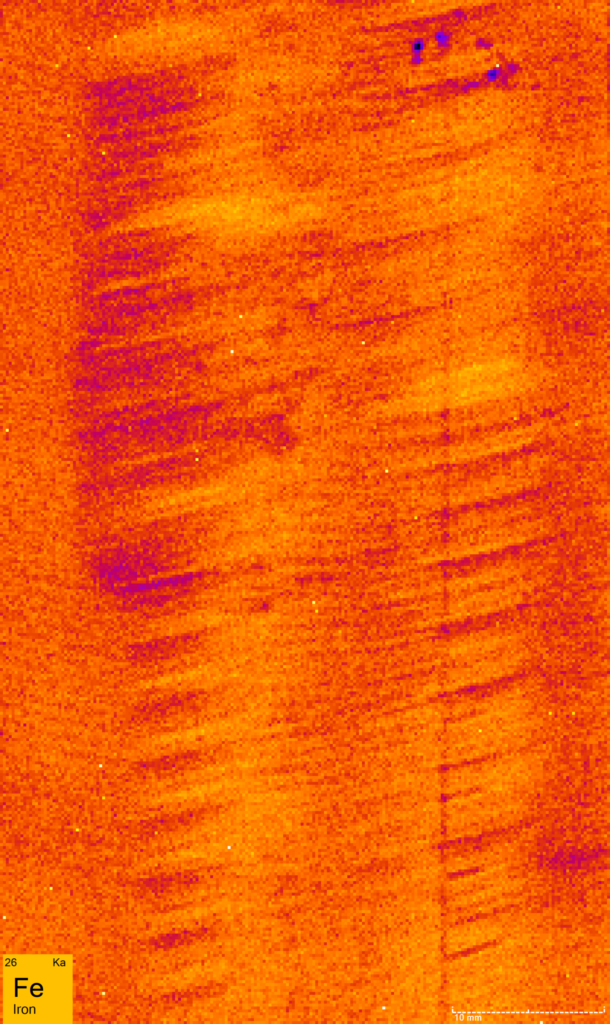

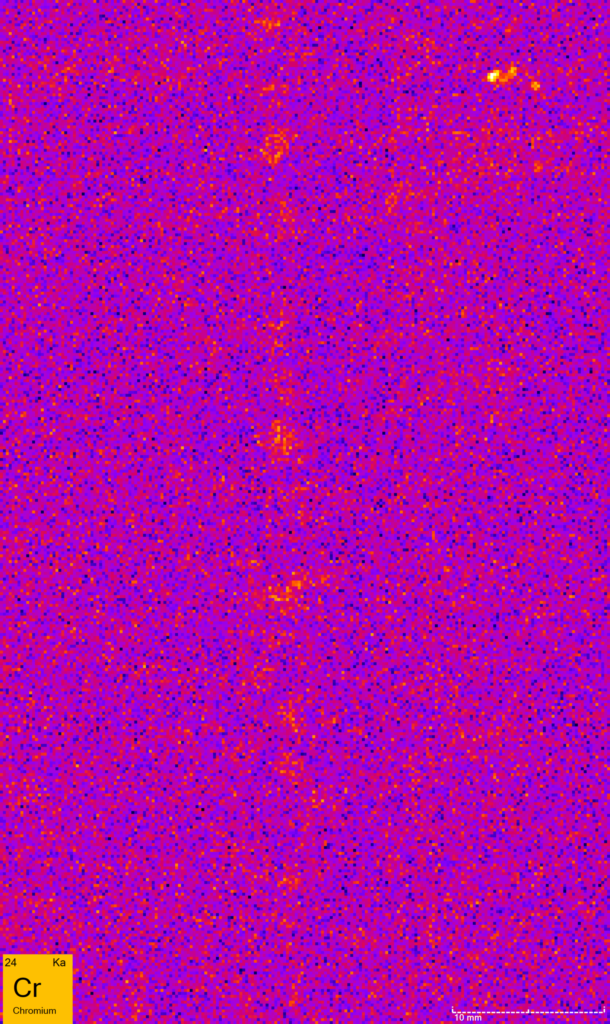

One of Veritas’ standout features is its 2D chemical mapping capability. This advanced feature allows users to visualize the spatial distribution of elements within a sample, providing profound insights into variations and anomalies that traditional bulk XRF methods might overlook. Manufacturers can better understand their materials with Veritas, leading to more informed decision-making.

Versatility Across a Broad Spectrum

Veritas’s highly efficient X-ray source can analyze elements ranging from carbon to uranium. This broad spectrum functionality ensures precise elemental analysis across various industries. Whether in automotive applications or industrial settings, Veritas adapts seamlessly to varying requirements, making it indispensable for diverse sectors.

Large Area Analysis for Expansive Applications

Tackling Extensive Sample Areas

Veritas excels in efficiently analyzing large sample areas, making it ideal for detailed and preliminary assessments. This feature is particularly beneficial for industries that require extensive sample analysis without compromising accuracy or detail. With Veritas, large-scale projects can proceed with confidence in the reliability of results.

High Sensitivity for Accurate Results

Veritas’s advanced detection capabilities provide exceptional sensitivity, particularly for high-Z elements. This precision is critical in steel slab analysis, where accurate readings of heavier elements determine the quality and performance of the final product. With Veritas, manufacturers gain a competitive edge through precise and reliable data.

Meeting High-Volume Demands

With faster analysis capabilities, Veritas is designed to meet the demands of high-volume environments. Its capacity to screen large samples quickly and effectively optimizes workflows, allowing businesses to operate efficiently. Veritas has become an invaluable partner in maintaining productivity and quality in fast-paced production settings.

Veritas in Action: Analyzing AHSS and UHSS Slabs

The Importance of Advanced Steel Grades

Advanced High-Strength Steel (AHSS) and Ultra-High-Strength Steel (UHSS) are pivotal in modern industrial applications due to their superior mechanical properties. These grades often include high alloy contents, such as manganese, silicon, and aluminum, to meet specific performance criteria. However, during continuous casting, alloying elements can segregate along the centerline of slabs, leading to defects that impact mechanical performance.

Overcoming Challenges in Traditional Analysis

Traditional methods for assessing the internal quality of steel slabs, like etching techniques, often fall short due to their qualitative nature. These methods are subjective and cannot provide quantitative data essential for technical benchmarking or statistical analysis. This limitation hinders steelmakers’ ability to accurately assess and control their products’ quality.

Bridging the Gap with Veritas

Veritas MacroXRF addresses these challenges head-on by offering a quantitative and objective approach to steel slab analysis. Its advanced 2D mapping capabilities generate detailed compositional maps of segregated areas, providing critical insights into the distribution of alloying elements along the centerline of AHSS and UHSS slabs. This precision mapping enables steelmakers to adjust casting parameters effectively, enhancing the quality of their products.

Figure 1: 2D XRF chemical maps of Advanced High-Strength Steel slab samples collected with the Veritas macro XRF using a 250um spot size. These maps were used to identify segregation defects in the production of steel slabs.

Key Benefits of Veritas for Steel Analysis

Detecting Segregation with Precision

The high-resolution 2D maps produced by Veritas provide a clear view of element distribution, which is crucial for identifying and mitigating segregation defects in steel slabs. This enhanced detection capacity allows manufacturers to proactively address potential issues, ensuring the integrity and performance of their steel products.

Quantitative Data for Informed Decisions

Veritas delivers quantitative data that can be used for benchmarking and improving casting processes. Generating detailed compositional maps equips manufacturers with the information to make informed decisions that optimize production and enhance overall product quality.

Streamlined Workflow Efficiency

Veritas’s automated capabilities reduce the need for manual intervention, speeding up the analysis process and enabling more frequent assessments. This efficiency is vital in high-volume production environments, where time and accuracy are critical to maintaining competitive advantage.

What’s Next?

Veritas continues to innovate and push the boundaries of MacroXRF technology. IXRF Systems is constantly researching and developing new techniques and algorithms to improve its capabilities and deliver even more precise and detailed results. With a commitment to providing top-of-the-line analysis solutions, Veritas is poised to lead the way in elemental analysis for the steel industry and beyond.

Conclusion

Veritas MacroXRF sets new standards in elemental analysis, particularly in evaluating AHSS and UHSS slabs. With its advanced mapping capabilities, high sensitivity, and efficient large-area analysis, Veritas not only addresses the limitations of traditional methods but also provides steelmakers with the tools needed to enhance product quality and meet the industry’s stringent demands. Whether in conservation, geology, or industrial applications, Veritas adapts to specific needs, making it the future of MacroXRF technology.

Kickstart Your Project Today!

Don’t miss the opportunity to revolutionize your elemental analysis with Veritas MacroXRF. Whether you’re in the steel industry, geology, or conservation, our cutting-edge technology is designed to meet your specific needs and exceed your expectations. Contact IXRF Systems today to learn how Veritas can transform your workflows and elevate your product quality. Contact us now and start your project with Veritas MacroXRF—leading the future of elemental analysis.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries.

Visit our website or contact our team directly to learn more about the Veritas macroXRF and how it can revolutionize your work.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries.