Concrete is one of the most widely used construction materials, essential in everything from residential buildings to massive infrastructure projects. However, ensuring its longevity and integrity requires detailed chemical analysis—particularly for issues like chloride ingress, alkali-silica reactions, and material heterogeneity.

Traditional techniques such as bulk XRF, SEM-EDS, and LIBS provide valuable insights. Still, they come with limitations regarding spatial resolution, sample preparation requirements, and the ability to analyze large samples. The Atlas X microXRF from IXRF Systems overcomes these limitations, offering a non-destructive, high-resolution, and highly efficient solution for analyzing concrete materials.

Why Choose MicroXRF for Concrete Analysis?

MicroXRF (µXRF) is a powerful elemental analysis technique that delivers both high-resolution imaging and quantification of elements in solid samples. When applied to concrete research and quality control, it offers several key benefits:

- Non-Destructive Analysis: Unlike traditional methods that require grinding, polishing, or acid digestion, µXRF directly analyzes concrete cores, thin sections, and surface samples without altering their structure.

- High Sensitivity to Chloride and Sulfate Ions: Chloride-induced corrosion is a significant threat to reinforced concrete structures. µXRF enables detailed mapping of chloride ingress, helping engineers assess concrete durability and develop better mitigation strategies.

- Large Sample Compatibility: The Atlas X µXRF features a large chamber, accommodating concrete cores and large samples that might not fit in conventional instruments. This is a significant advantage over techniques like SEM-EDS, which require extensive sample preparation and can only analyze small areas.

- Automated Elemental Mapping: Creating high-resolution elemental maps enables researchers to visualize elemental distributions across large surface areas—critical for studying alkali-silica reaction (ASR), carbonation, and contamination from de-icing salts.

Advantages Over Alternative Techniques

Several traditional methods are used to analyze concrete composition and degradation processes, including bulk XRF, SEM-EDS, and LIBS. Here’s how µXRF compares:

1. µXRF vs. Bulk XRF

| Feature | µXRF | Bulk XRF |

| Spatial Resolution | High (<150 µm) | Low (averages entire sample) |

| Elemental Mapping | Yes, large-area capability | No |

| Sample Preparation | Minimal or none | Requires pulverization |

| Detection of Chlorides and Sulfates | Localized, high-resolution | Bulk averaging |

- Why µXRF Wins: Bulk XRF provides average composition but lacks spatial resolution. µXRF delivers localized information, allowing users to study the penetration depth of corrosive elements without destroying the sample.

2. µXRF vs. SEM-EDS

| Feature | µXRF | SEM-EDS |

| Sample Size | Large (whole cores, slabs) | Small (thin sections) |

| Sample Prep | Minimal | Requires vacuum compatibility and coating |

| Speed | Fast, automated mapping | Slow, point-by-point analysis |

| Penetration Depth | Tens to hundreds of microns | Surface-level (~1-2 µm) |

- Why µXRF Wins: While SEM-EDS provides excellent micro-scale detail, it requires time-consuming preparation and is limited in analyzing large, intact samples. µXRF, on the other hand, allows for wide-area analysis without complex sample prep, making it ideal for field samples and rapid screening.

3. µXRF vs. LIBS (Laser-Induced Breakdown Spectroscopy)

| Feature | µXRF | LIBS |

| Detection Limits | Superior for mid-to-heavy elements | Best for light elements (Li, Be, B) |

| Spatial Resolution | High (<150 µm) | Moderate (depends on laser spot) |

| Sample Damage | None | Ablative (destroys sample) |

| Quantification Accuracy | High | Moderate (requires more calibration) |

- Why µXRF Wins: LIBS is excellent for light elements but can damage samples, making it unsuitable for non-destructive applications. µXRF, in contrast, provides precise, quantitative data without destroying valuable samples.

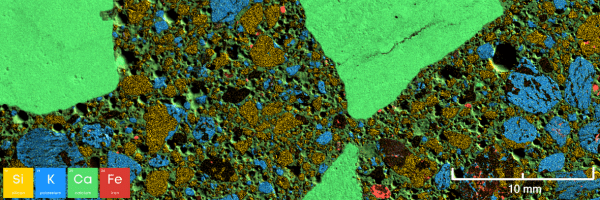

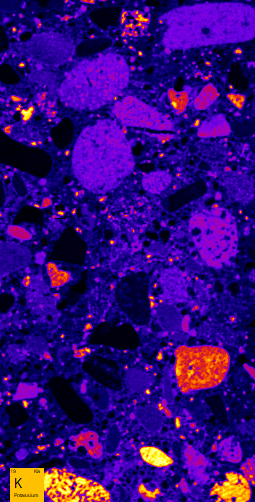

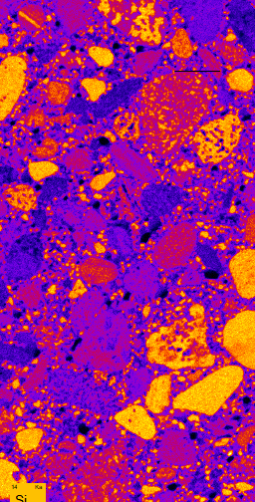

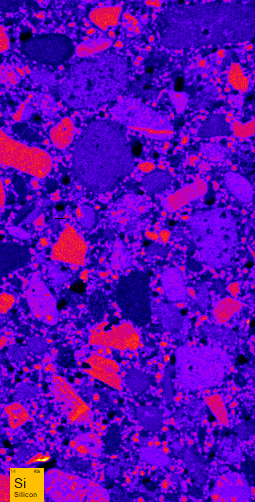

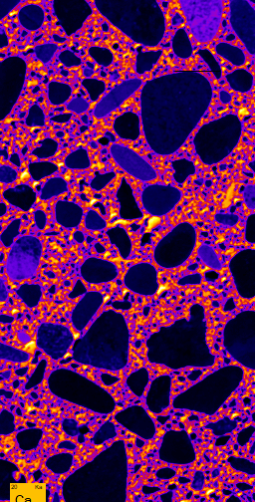

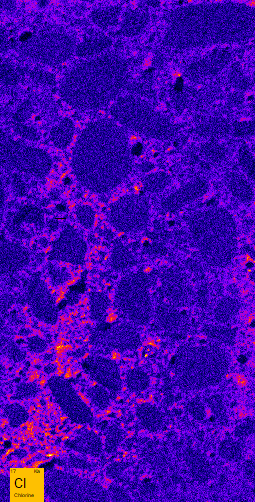

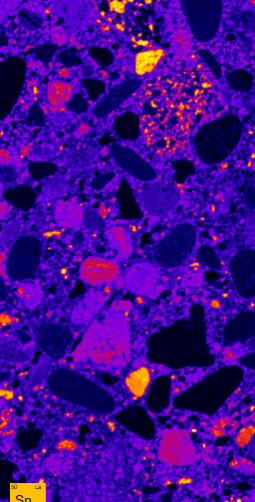

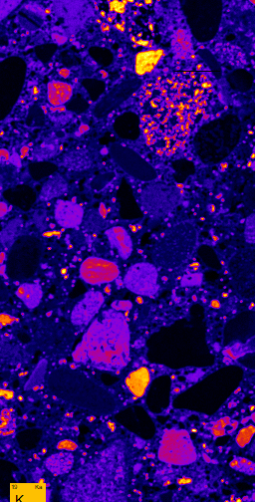

Figure 1: 2D microXRF maps of a concrete slab

Key Applications of the Atlas X in Concrete Research

The Atlas X µXRF system is particularly valuable in several critical concrete degradation applications:

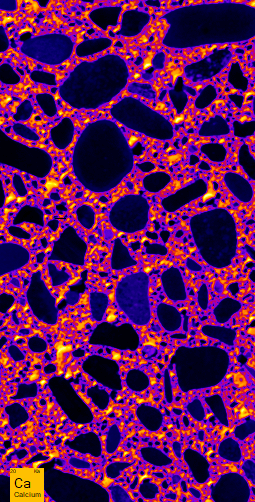

1. Chloride Ingress and Corrosion Studies

- Chloride penetration in concrete is a leading cause of steel reinforcement corrosion. By mapping chloride concentrations across concrete sections, researchers can determine how far chlorides have penetrated and assess the effectiveness of different concrete formulations in resisting ingress.

- Research on 3D-printed concrete has demonstrated how cold joints impact chloride diffusion, highlighting the need for spatially resolved elemental analysis to assess durability.

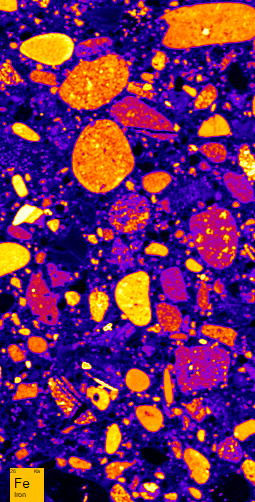

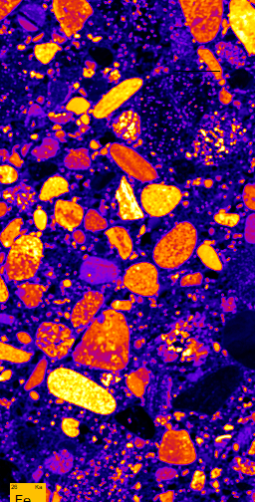

2. Alkali-Silica Reaction (ASR) and Material Durability

- ASR is a chemical reaction between alkalis in cement and reactive silica in aggregates, leading to expansion and cracking in concrete. µXRF can map reactive silica distributions and identify early-stage ASR deterioration.

3. Cement Composition and Supplementary Materials

- µXRF enables the characterization of cement phases, including blended cement, fly ash, slag, and pozzolans, helping manufacturers optimize formulations for enhanced durability.

4. Heavy Metal and Contaminant Detection

- Industrial and environmental factors can introduce heavy metals, sulfates, and other contaminants into concrete. The Atlas X allows for high-sensitivity detection of toxic elements, ensuring compliance with regulatory standards.

Conclusion: The Atlas X MicroXRF – The Future of Concrete Analysis

The Atlas X µXRF offers a revolutionary approach to concrete analysis, outperforming bulk XRF, SEM-EDS, and LIBS in key areas. Its large chamber design, high spatial resolution, and non-destructive capabilities provide a powerful tool for quality control, failure analysis, and research applications in the concrete industry.

From assessing chloride ingress to detecting ASR damage and analyzing cement composition, the Atlas X redefines how materials scientists and engineers study concrete durability. Whether in construction quality control, academic research, or infrastructure maintenance, µXRF is the preferred technique for precise, high-resolution chemical analysis.

For more information on how the Atlas X microXRF can enhance your concrete analysis workflows, contact IXRF Systems today.