Mining has long been the backbone of industrialization, providing the world with essential resources. However, the byproducts of mining operations, often referred to as mine waste, can be a source of significant environmental concern. With the growing demand for sustainability and effective environmental management, there’s an increasing emphasis on the accurate monitoring and analysis of mine waste. Enter microXRF, a cutting-edge technique that promises unparalleled accuracy in analyzing mine waste samples. This article delves deep into the world of mine waste, its environmental impact, and the role of microXRF in addressing these challenges.

The Environmental Challenge of Mine Waste

Mine waste, sometimes called tailings, refers to the leftover material once the valuable minerals have been extracted. Typically, these residues are disposed of in tailings dams or heaps. While these waste products may seem harmless, they often contain hazardous materials that can have severe environmental consequences:

Water Pollution

When rainwater seeps through tailings, it can leach out harmful substances such as arsenic, cyanide, and heavy metals. These toxic chemicals can contaminate local water sources, harming aquatic life and posing a threat to human health.

Soil Degradation

Over time, the chemicals in mine waste can degrade the quality of the soil, making it less fertile and even toxic for plants.

Airborne Contaminants

The wind can blow dust from tailings heaps, carrying small particles laden with harmful substances. This can lead to respiratory ailments in humans and animals and contaminate farmland.

Given these potential hazards, there’s an urgent need for accurate monitoring and management of mine waste.

The Power of MicroXRF

X-ray fluorescence (XRF) has been used to analyze the composition of various materials. MicroXRF, as the name suggests, is a refined version of this technique, enabling analysis at a microscopic scale, as small as 5 µm with the Atlas series microXRF. Here’s why microXRF stands out as a go-to method for mine waste analysis:

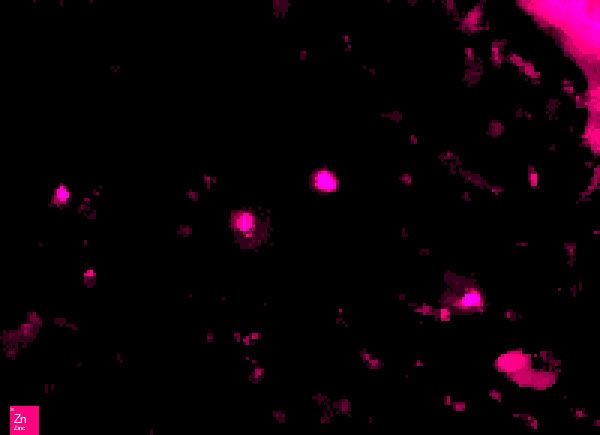

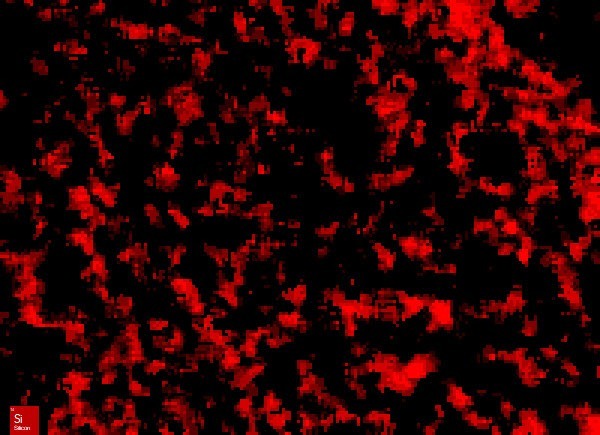

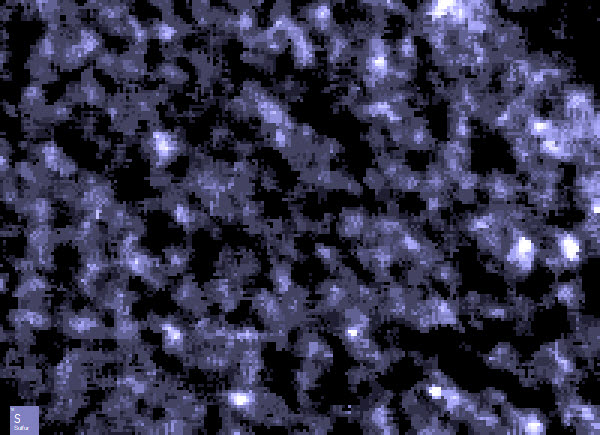

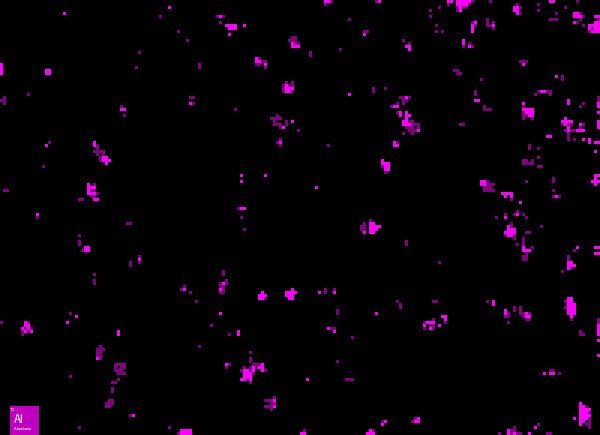

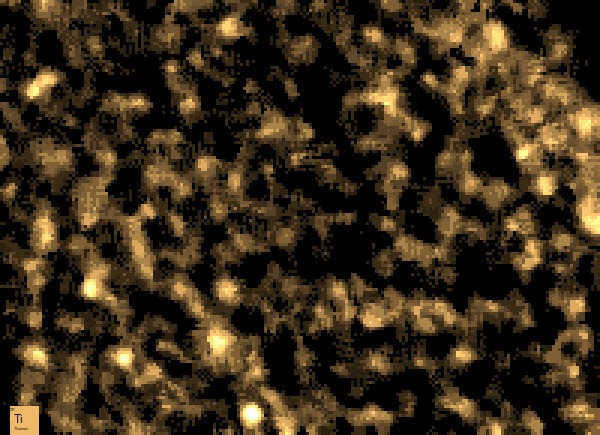

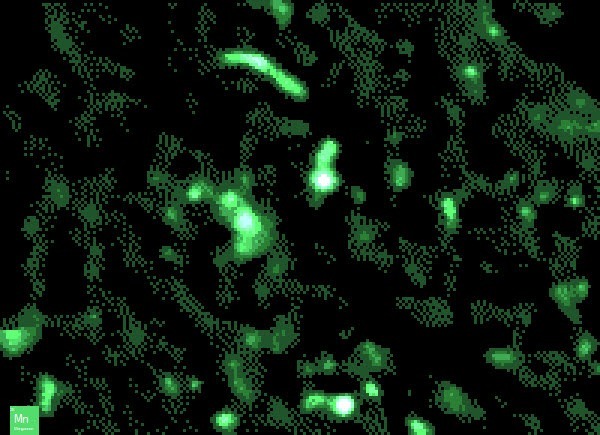

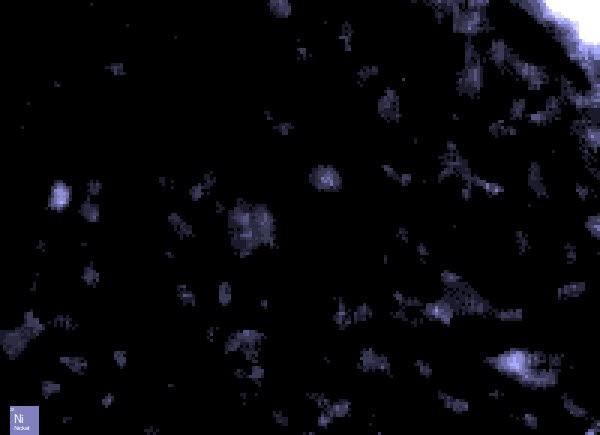

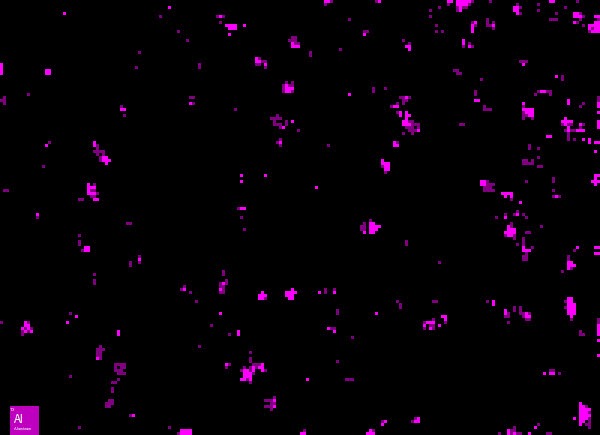

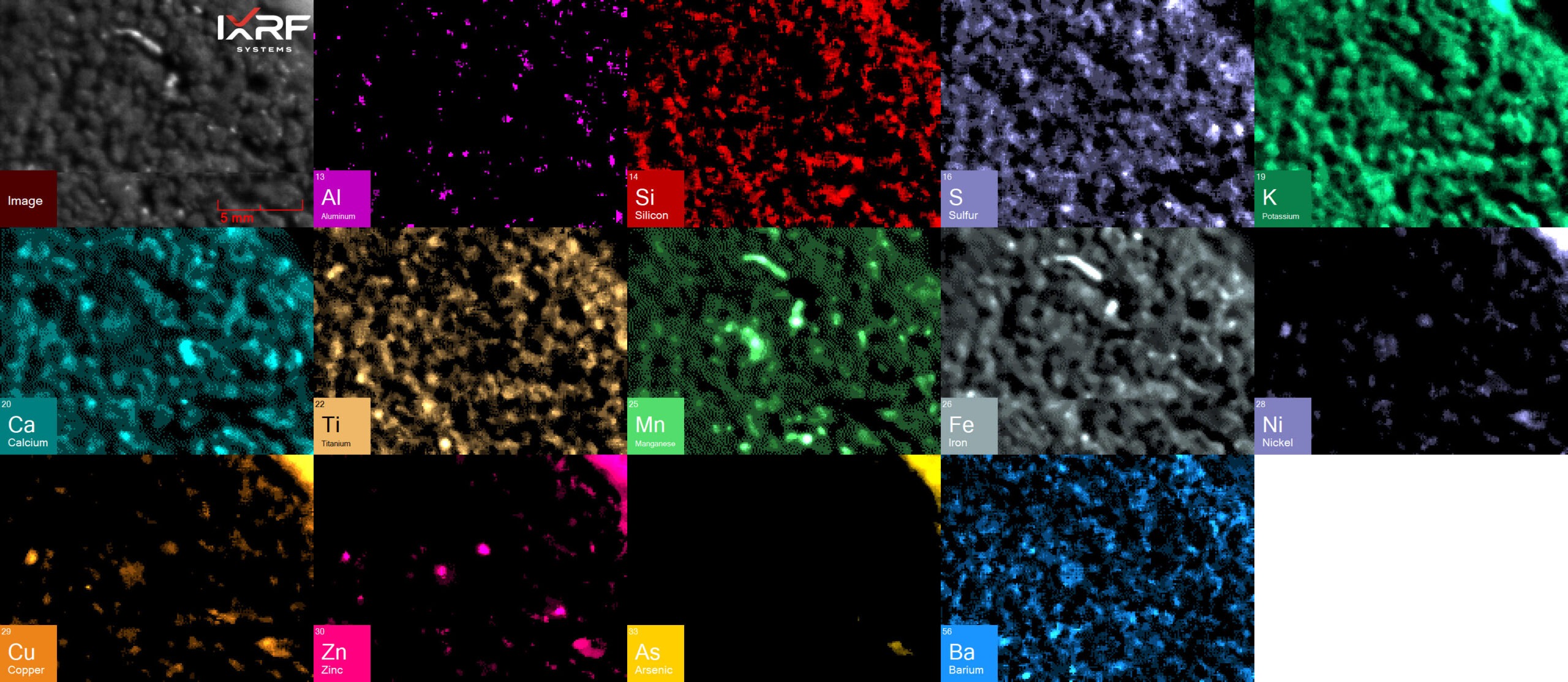

Figure 1: Elemental maps of granular mine waste. Each sample was packed in an XRF sample cup lined with mylar film and was analyzed by the Atlas X microXRF using a spot size of 96 microns. The sample contained the following elements: Al, Si, S, K, Ca, Ti, Mn, Fe, Ni, Cu, Zn, As, and Ba.

High-Resolution Imaging

MicroXRF provides detailed elemental and morphological maps, showing the distribution of elements in the sample. This precision is vital for identifying specific contaminants in heterogeneous waste samples. A technique comparable to microXRF is Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy (SEM-EDS), but it primarily focuses on surface analysis, potentially overlooking deeper compositional details. Additionally, while SEM-EDS has a detection limit of approximately 0.1 wt%, microXRF can detect levels as low as <10 ppm, contingent upon the element of interest and the sample matrix.

Non-Destructive Analysis

Unlike techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS) or Atomic Absorption Spectrometry (AAS) that frequently demand extensive sample preparation, such as acid digestion, microXRF preserves the sample’s original state, permitting repeated analyses if required.

Rapid Results

Speed is of the essence when addressing environmental hazards. MicroXRF provides quick and accurate results with minimal sample preparation, aiding in timely decision-making.

Versatility

From heavy metals to rare earth elements, microXRF can detect a wide range of elements from carbon to americium (C – Am), making it ideal for the diverse compositions found in mine waste.

Case Studies: MicroXRF in Action

Several mining companies and research institutions have already adopted microXRF for mine waste analysis. For example:

- A study in South Africa used microXRF to analyze tailings from gold mines. Researchers could pinpoint areas with high concentrations of arsenic, aiding in targeted remediation efforts.

- In Australia, microXRF was instrumental in studying waste from copper mines. The detailed elemental maps allowed scientists to understand the mobility of contaminants and devise strategies to limit their spread.

Figure 2: Individual element maps of granular mine waste displayed in the following order of elements: Al, Si, S, K, Ca, Ti, Mn, Fe, Ni, Cu, Zn, As, and Ba.

The Road Ahead

While microXRF is a powerful tool, viewing it as part of a broader environmental protection strategy is essential. Effective mine waste management requires an integrated approach, combining advanced analysis techniques with robust policy frameworks and community engagement.

In conclusion, as the world grapples with the dual challenges of meeting its resource needs and ensuring environmental protection, techniques like microXRF will be at the forefront of sustainable mining practices. By enabling accurate, rapid, and non-destructive analysis of mine waste, microXRF promises a brighter, cleaner future for mining communities and the environment at large.

Let’s Learn and Lead: Explore MicroXRF Further

The relationship between industrial practices and environmental impact is complex. One way to navigate this complexity is by being informed. MicroXRF presents a significant advancement in analyzing mine waste, offering precision and efficiency.

If you’re curious about the intersection of technology and environmental management, delving into microXRF is a logical next step. Equip yourself with knowledge, ask questions, and understand the practical applications of this tool.

Are you interested in the technologies shaping our environmental solutions? Delve deeper into microXRF and its potential for sustainable mining practices. A better-informed community leads to better decisions.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries.