Brake pads are critical safety components in vehicles, playing a pivotal role in the braking system by allowing cars, trucks, and other vehicles to stop efficiently and safely. The choice of materials in brake pads is essential not only for performance but also for the longevity and reliability of the brake system. This article explores the unique characteristics of brake pad materials and discusses how high-spatial-resolution microXRF (X-ray fluorescence) spectroscopy can be a powerful tool for analyzing these materials.

Figure 1: Image of a brake pad surface.

Unique Characteristics of Brake Pad Materials

Brake pads must withstand extreme conditions, including high temperatures, pressure, and friction. They are typically made from a composite of materials that can include metals, ceramics, and organic compounds. Each material type offers different properties:

Metallic Pads: These pads are durable and offer excellent heat transfer capabilities. They are made from a mix of metals such as steel, iron, copper, and other alloys. Metallic pads are favored in high-performance and heavy vehicles due to their durability and ability to withstand high temperatures.

Ceramic Pads: Composed primarily of ceramic fibers, nonferrous filler materials, and bonding agents, ceramic brake pads are quieter and offer finer dust compared to metallic pads, which reduces the wear on the brake system. They also perform well under a wide range of temperatures and driving conditions.

Organic Pads: Made from glass, rubber, carbon compounds, and more, bonded with resin, organic pads are softer and quieter. They are effective for general use in lighter vehicles and are less harsh on brake discs.

Each type of material composition affects the performance characteristics of brake pads, such as noise, dust production, and wear resistance. As vehicle performance requirements increase and environmental regulations become stricter, the development of advanced brake pad materials becomes crucial.

Traditional Analytical Instrumentation for Brake Pad Materials

Analyzing brake pad materials involves several traditional techniques, each contributing valuable insights into the material’s composition and properties:

1. Scanning Electron Microscopy (SEM): Provides detailed images of the surface structure, useful for examining wear patterns and material degradation.

2. Energy Dispersive X-ray Spectroscopy (EDS): Often coupled with SEM, EDS analyzes the elemental composition at specific points or regions in a sample.

3. X-ray Diffraction (XRD): Used to identify crystalline phases and to understand the crystallographic structure of the materials used in brake pads.

4. Inductively Coupled Plasma (ICP): Offers quantitative analysis of metals in brake pads, crucial for formulations that rely heavily on metallic components.

5. Fourier Transform Infrared Spectroscopy (FTIR): Helps in identifying organic compounds in the brake pads, such as resins and rubber used in organic and ceramic pads.

These techniques have been instrumental in advancing brake pad technology by allowing detailed examination of material properties and failures.

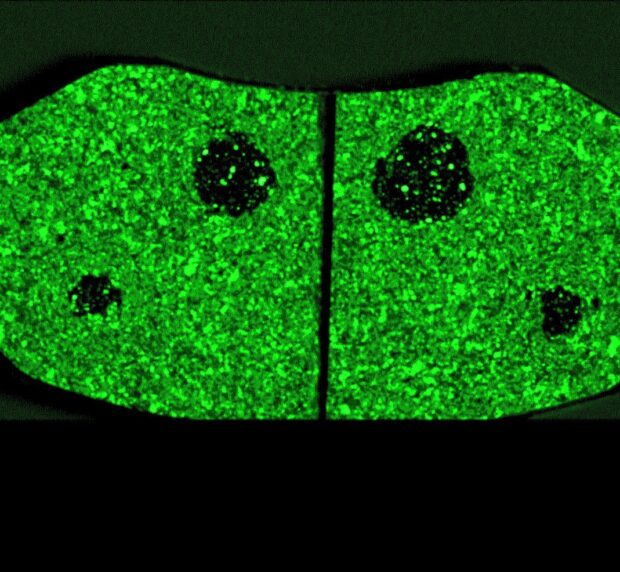

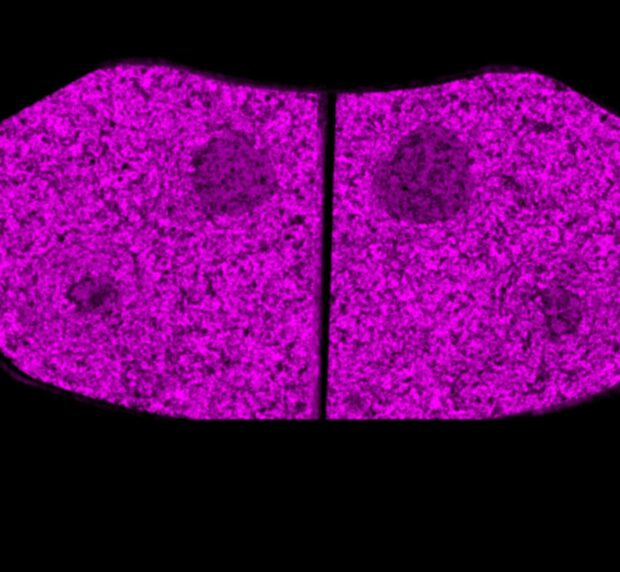

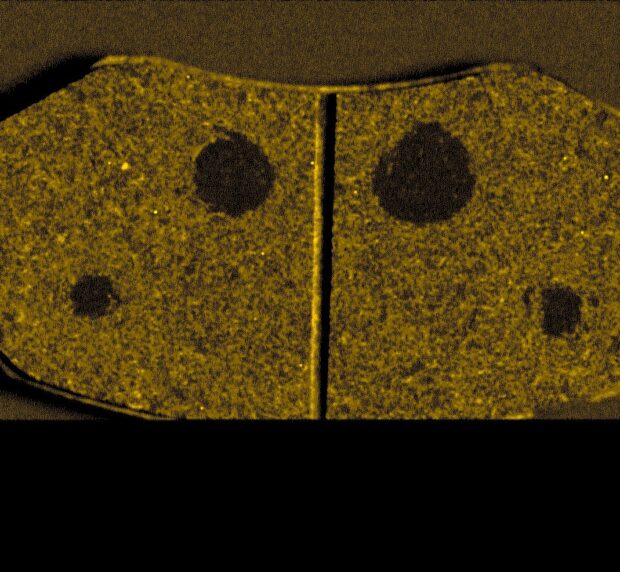

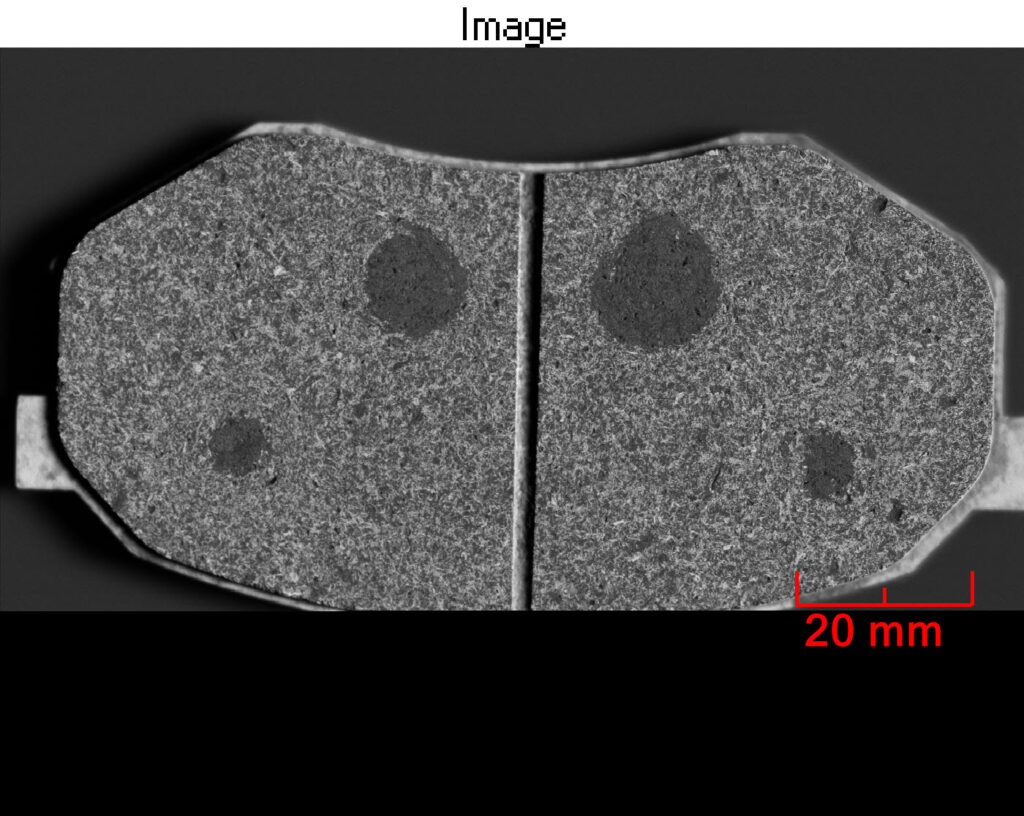

Figure 2: Select element maps of a brake pad displayed above in the following order of elements: Zn, Ti, S, Mn, K, Fe, Cu, Ca, and Ba.

Advantages of MicroXRF in Brake Pad Analysis

MicroX-ray fluorescence (microXRF) spectroscopy brings several enhancements over traditional methods, particularly in terms of efficiency, comprehensiveness, and non-destructiveness:

· Non-Destructive Testing: Unlike some traditional methods that may require the destruction of a sample (like in some ICP analyses), microXRF is completely non-destructive. This allows for the analysis of the same sample under different conditions or after different stress tests without altering its structure.

· Elemental Mapping: MicroXRF provides comprehensive maps of elemental distribution across the brake pad, not just at specific points. This holistic view is crucial for understanding the uniformity of the pad’s composition and for identifying areas of material concentration that could affect performance.

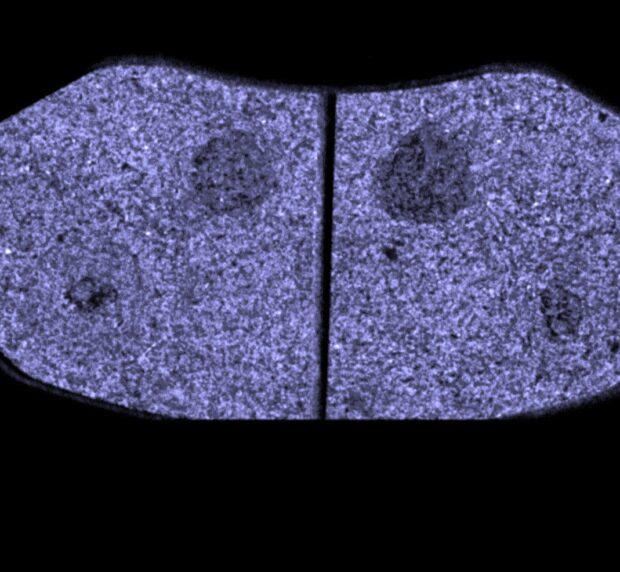

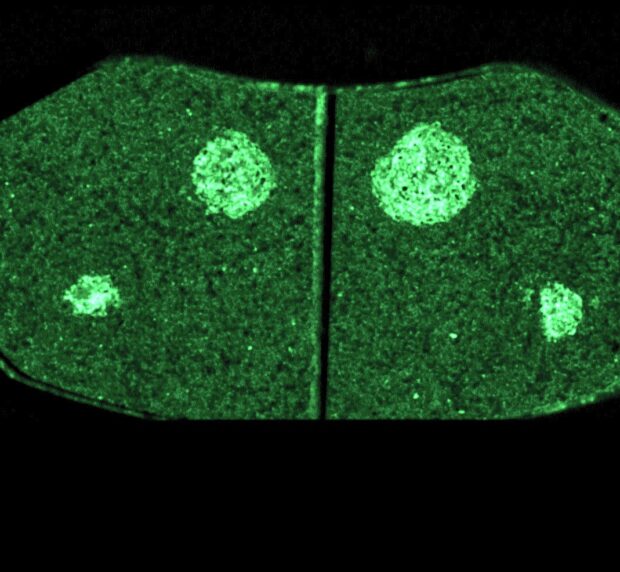

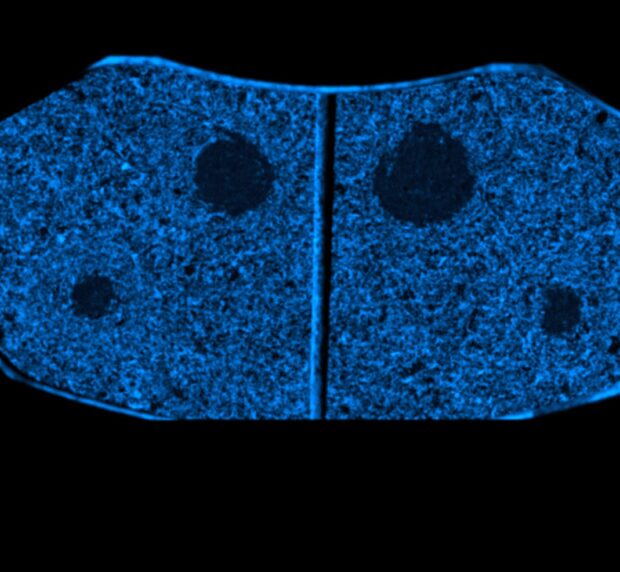

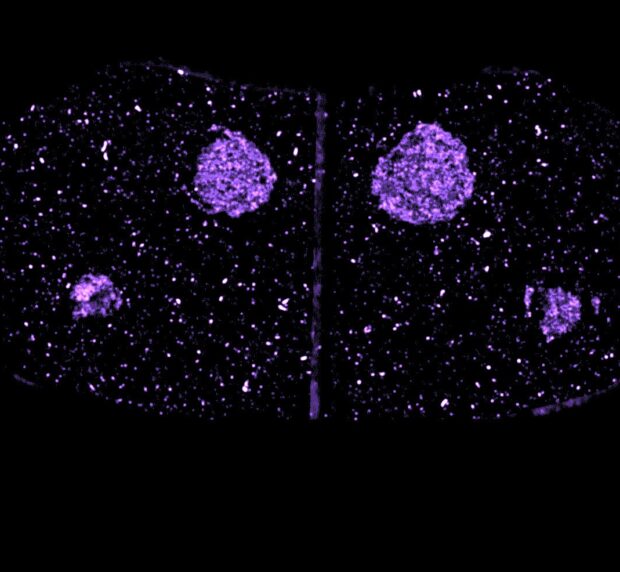

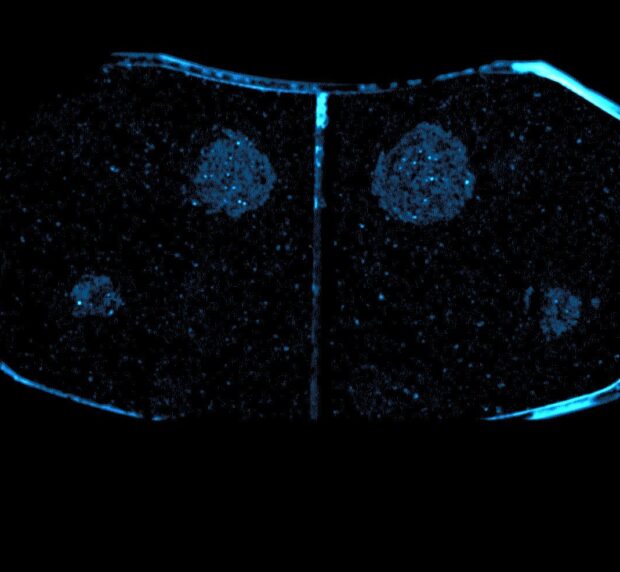

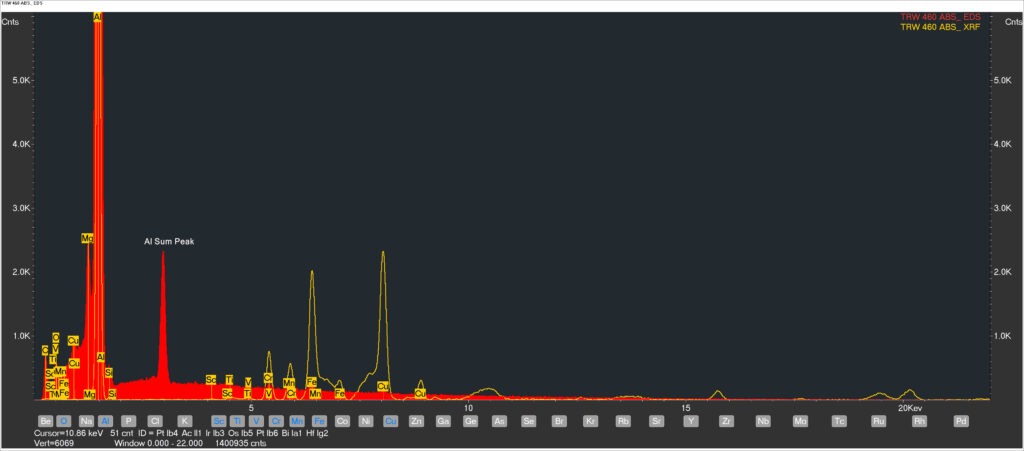

Figure 3: Element maps of a brake pad displayed in the following order of elements: S, K, Ca, Ti, Mn, Fe, Ni, Cu, Zn and Ba. This sample was acquired on the Atlas X using a 5 μm pixel size.

· Simultaneous Multi-Element Analysis: Unlike EDS, which is limited by the beam interaction volume and may require multiple scans, microXRF can simultaneously analyze multiple elements across a large area, significantly speeding up the analysis process.

· Higher Sensitivity and Detection Limits: MicroXRF excels in detecting and analyzing higher atomic number (Z) elements with greater sensitivity and lower detection limits than other techniques. This capability is vital for accurately quantifying trace elements that significantly influence material properties despite their low concentrations.

· Minimal Sample Preparation: MicroXRF requires minimal sample preparation compared to methods like XRD or ICP, where extensive sample processing might be necessary. This saves time and preserves the integrity of the original sample.

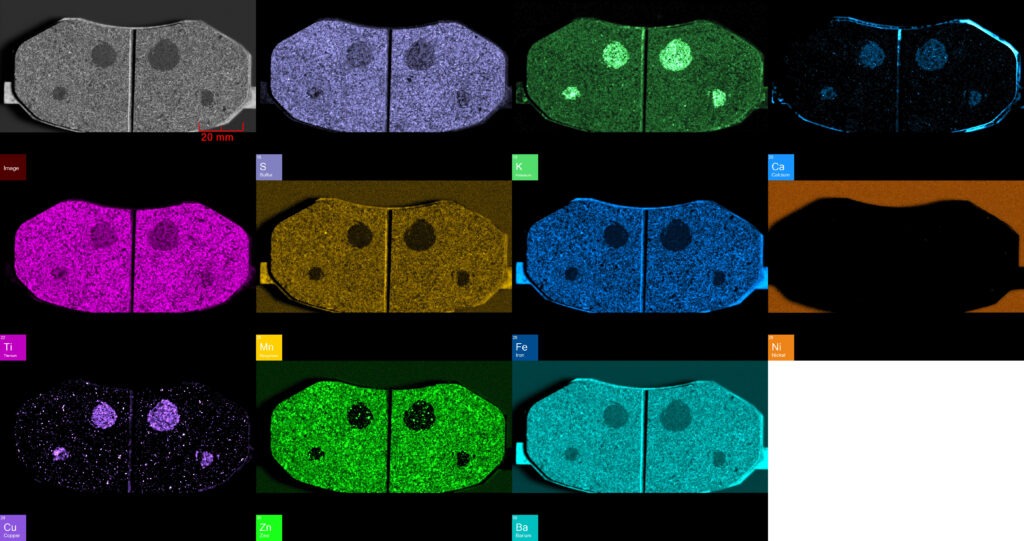

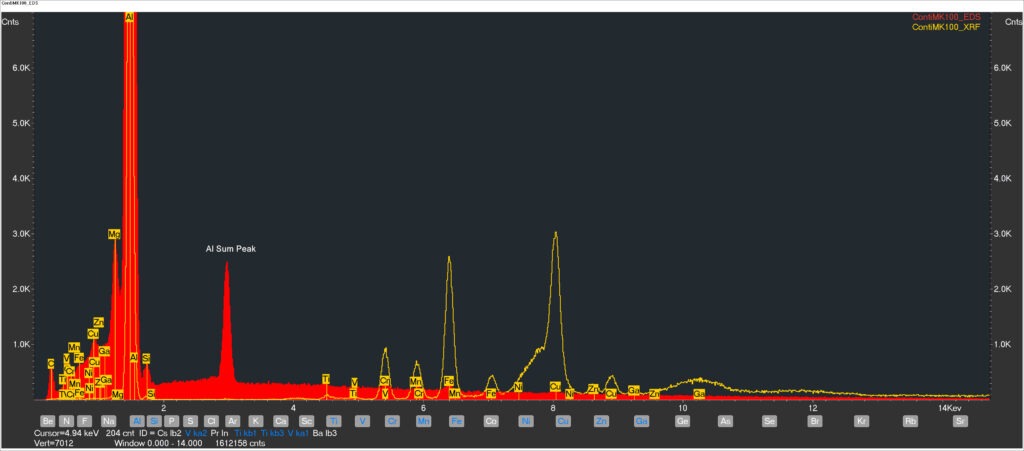

Figures 4 & 5: XRF spectrum of a brake pad.

Conclusion

While traditional methods like SEM, EDS, XRD, ICP, and FTIR continue to be valuable in the analysis of brake pad materials, the introduction of high-spatial-resolution microXRF spectroscopy offers a superior blend of detail, efficiency, and non-invasive analysis. Its ability to provide comprehensive elemental maps and analyze materials non-destructively makes microXRF an invaluable tool in the ongoing quest to develop safer, more effective brake pads. This advanced analytical capability not only ensures higher standards in manufacturing but also fosters innovation in brake pad technology, crucial for meeting the increasing demands of modern vehicles.

If you’re interested in enhancing your material analysis with lab-based microXRF, consider reaching out to IXRF Systems. Our team is equipped to show you how our advanced microXRF technology can be tailored to meet your specific needs, whether for research or industrial applications. Get in touch with us today to explore the possibilities and discuss how we can help improve your analytical capabilities. Contact IXRF Systems to learn more and take the next step towards precise and efficient material analysis.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries.