Among non-destructive analytical techniques, micro X-ray fluorescence (microXRF, microEDXRF, µXRF, µEDXRF) has emerged as a versatile tool for elemental characterization of various samples. This powerful method provides valuable insights into the composition and chemical states of the materials being analyzed. However, one of the most commonly asked questions about this technique is: “What is the penetration depth of X-ray radiation into a sample?” This article explores this question and examines the factors that influence penetration depth.

Determining Factors for X-ray Penetration Depth

The penetration depth of X-rays during microXRF analysis is not a fixed value; it depends on several key factors:

1. X-ray Energy

The energy of the X-rays plays a critical role. Higher-energy X-rays have greater penetrating power, allowing them to penetrate the sample deeper. Adjusting the X-ray energy based on the specific application is a common practice in microXRF to optimize the depth of analysis.

2. Material Density

The density of the material significantly impacts X-ray penetration. Denser materials absorb more X-rays, resulting in a shallower penetration depth. For example, metals and high-density ceramics will limit penetration more than low-density polymers or biological samples.

3. Atomic Number (Z)

The atomic number of the elements within the material also affects penetration depth. Materials with higher atomic numbers are more effective at stopping X-rays, leading to reduced penetration depth. This is particularly relevant for samples containing heavy elements like lead or gold.

4. XRF Technique

Different XRF techniques are tailored for varying depths of analysis:

- Total Reflection XRF (TXRF): Focused on surface-level analysis.

- Conventional microXRF: Capable of probing deeper into the material.

The choice of technique determines whether the focus is on surface characterization or subsurface layers.

XRF Information Depth: How Deep Can X-rays Penetrate?

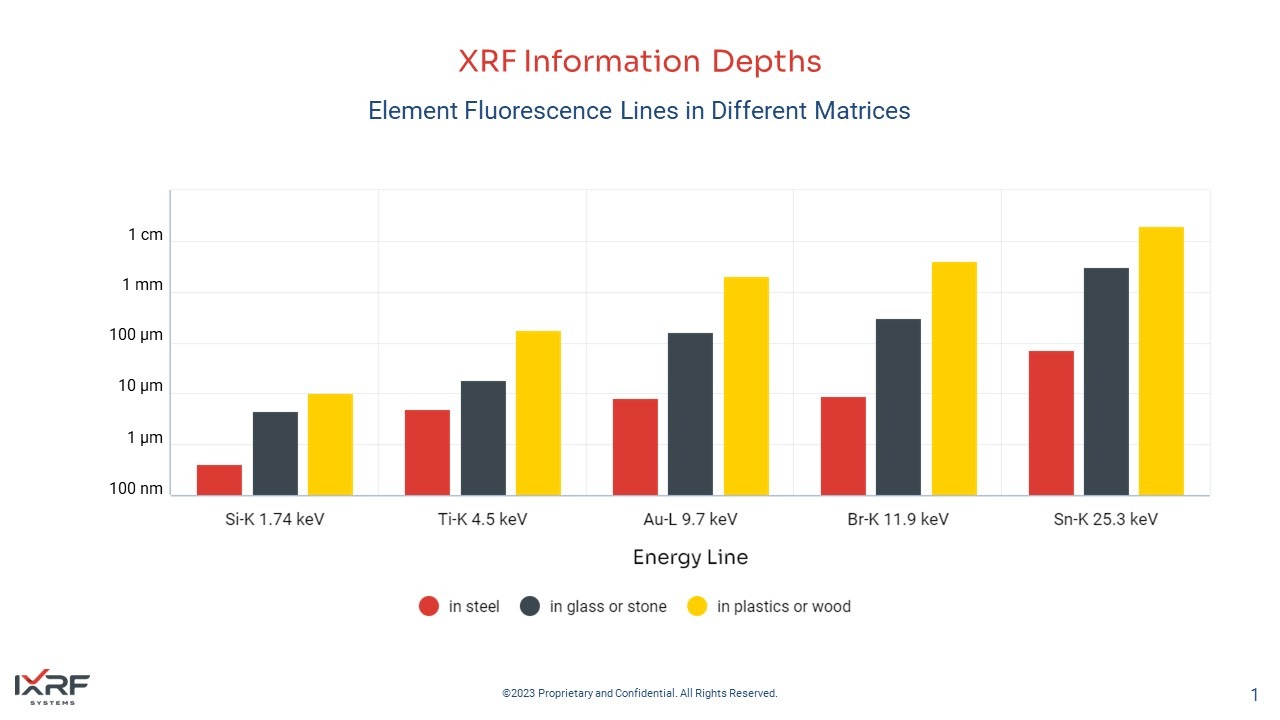

Given the factors above, the penetration depth of X-rays in microXRF analysis can vary significantly. As a general guideline, it ranges from a few micrometers to several millimeters. This versatility allows microXRF to analyze both surface and subsurface layers of materials.

For precise quantitative analysis, the specific parameters of the XRF system and the sample’s properties must be considered. Calibration and system optimization are essential to ensure accurate depth profiling.

Conclusion

The world of microXRF is fascinating, with applications in diverse industries such as archaeology, geology, materials science, and semiconductors. Understanding the factors that influence X-ray penetration depth is crucial for maximizing the potential of this analytical tool. Tailoring the analysis to your system and sample characteristics can achieve optimal results.

Stay curious and continue exploring the capabilities of microXRF! If you have questions or need further information, click the ASK FOR MORE INFO button below. We’re here to help you delve deeper into this exciting field.

Stay tuned for our next article!